In the fast-paced world of construction, precision is critical. For this to happen and for a project to be successful there is one crucial element. A watertight quantity takeoff (QTO) process. Historically, QTOs were manual processes, relying on skilled professionals and paper plans. However, modern software solutions now provide a much faster and more efficient approach.

What are Quantity Takeoffs?

Quantity takeoffs in construction refer to the detailed measurement and listing of materials, labour, and equipment required for a construction project. This process involves analysing construction drawings and specifications to determine the exact quantities needed for each component of the project. There are several key factors that need to be considered: Here are the key points about quantity takeoffs:

- Material Estimation: Identifying and quantifying all the materials necessary, such as concrete, steel, wood, and other building supplies.

- Labour Requirements: Estimating the amount of labour needed to complete the project, including different trades and skill levels.

- Equipment Needs: Determining the equipment required for various stages of construction, like cranes, excavators, and scaffolding.

- Accuracy and Detail: Ensuring the takeoff is precise and comprehensive, as inaccuracies can lead to budget overruns or project delays.

- Software Tools: Utilising specialised software to assist in creating detailed and accurate takeoffs, enhancing efficiency, and reducing human error.

- Cost Estimation: Forming the basis for the project's cost estimate, which is essential for budgeting, bidding, and financial planning.

Quantity takeoffs are crucial for ensuring that a construction project is carefully planned, budgeted, and executed, otherwise the project’s overall success and efficiency can be in jeopardy. Let us look at the methodology of the traditional approach versus the modern approach now.

Traditional QTO Methods: A Tried-and-Tested Approach

Traditional QTOs involve manually extracting measurements and material quantities from 2D drawings. This process demands:

- Skilled Quantity Surveyors: These professionals interpret drawings, apply formulas, and calculate quantities with precision.

- Time-consuming Calculations: Manual calculations, especially for complex projects, are prone to errors and can be labor-intensive.

- Paper-based Workflows: Physical plans and documents are used for measurements and record-keeping, limiting collaboration and information sharing.

Quantity surveyors play a pivotal role in traditional QTO methods by:

- Interpreting Drawings and Specifications: They meticulously analyse project drawings and specifications to identify all required materials.

- Calculating Quantities: Applying industry-standard formulas and techniques ensures accurate estimation of material quantities.

- Creating Take-off Documents: Compiling detailed calculations into comprehensive takeoff documents forms the basis for cost estimates.

- Maintaining Accuracy: Ensuring the correctness of calculations is crucial to prevent costly errors during project execution.

However, these methods are not without limitations. Manual calculations can be time-consuming and susceptible to human error, particularly for intricate projects. Additionally, reliance on paper-based workflows can hinder collaboration and information sharing amongst stakeholders.

Modern QTO Methods: Embracing Efficiency and Accuracy

Modern QTO methods leverage advanced software solutions that offer several advantages:

- Automated Calculations: Software tools can automatically extract measurements and compute quantities directly from digital plans (2D or 3D models), reducing time and human error.

- Improved Collaboration: Digital workflows facilitate seamless data sharing and access to QTO data, enhancing communication and project management.

- Enhanced Accuracy: Software ensures consistency and minimises errors in calculations, providing reliable estimates.

- Integration with Estimating: QTO data integrates smoothly with estimating software, enabling faster and more accurate cost calculations.

Advantages of Using Modern QTO Software

An article by RIBCCS, stated that going digital reduces the risk of error, minimises wastage, and increases efficiency. Modern QTO software outshines traditional methods in several aspects:

- Increased Speed and Efficiency: Automation accelerates QTO processes significantly, speeding up project timelines.

- Reduced Errors: Minimised human intervention lowers the risk of errors, leading to more precise cost estimates and fewer project overruns.

- Improved Collaboration: Digital tools promote effective collaboration among stakeholders, enhancing project transparency and accountability.

- Enhanced Cost Estimating: Accurate QTO data enables precise budgeting and financial planning, supporting better project control.

- Greater Transparency: Digital workflows provide clear audit trails of QTO calculations, enhancing project governance and decision-making.

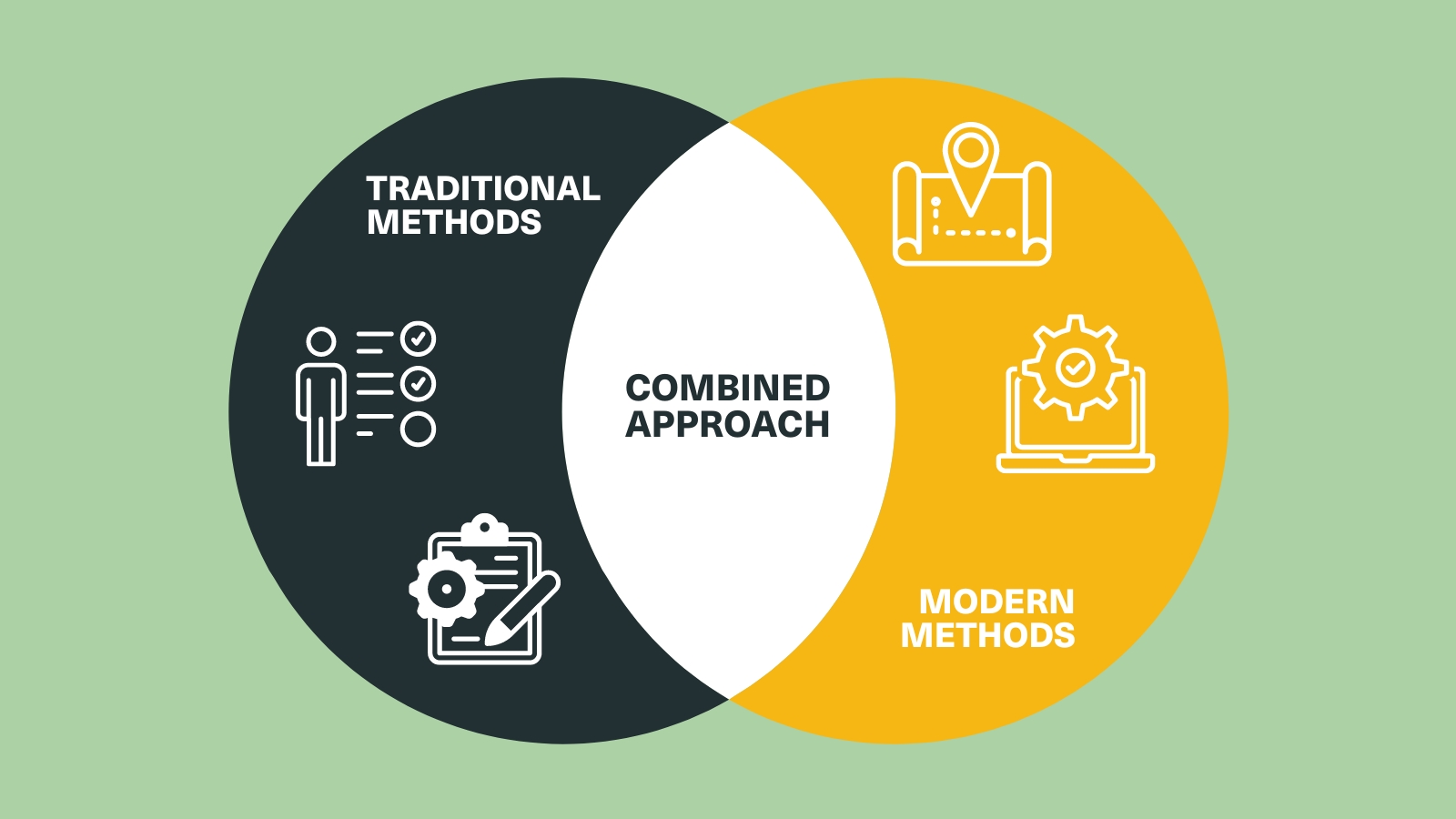

Combining the Best of Both Worlds

While modern software offers substantial benefits for large or complex projects, traditional methods remain relevant, particularly for smaller projects or where expertise is readily available. The optimal approach often involves:

- Leveraging Software for Efficiency: Automating routine calculations with software streamlines processes and improves accuracy for most materials.

- Utilising Skilled Professionals: Experienced quantity surveyors are invaluable for complex calculations or specialised materials, ensuring accuracy and reliability.

Neither traditional nor modern methods exist in a vacuum. The optimal approach often lies in a strategic combination of both. For smaller projects or those requiring specialised expertise, leveraging the experience of skilled quantity surveyors with traditional methods can still be highly advantageous. However, for large-scale or complex projects, the benefits of modern software in terms of efficiency and accuracy become invaluable.

Benefits of a Modern Approach

Embracing modern QTO methods translates into multiple advantages for construction companies:

- Cost Reduction: Faster QTOs and fewer errors result in more accurate estimates, minimising project costs and enhancing profitability.

- Enhanced Efficiency: Automated calculations and streamlined workflows free up resources for other critical tasks, boosting overall project efficiency.

- Improved Collaboration: Digital tools foster seamless data sharing and collaboration, enhancing teamwork and decision-making.

- Better Project Control: Accurate QTOs provide a solid foundation for project planning, scheduling, and resource allocation.

Embrace the Future of QTOs

Whether opting for traditional methods or embracing modern software, a robust QTO process is pivotal for successful construction projects. Understanding the strengths and limitations of each approach empowers construction professionals to choose the best-fit solution, ensuring a smooth, efficient, and cost-effective project journey.

This exploration of QTO methods equips you with the knowledge to navigate the evolving landscape. By strategically selecting the right approach for your project, you can ensure that your next construction endeavor is a resounding success, playing a part in construction excellence.

About us

At Stonehaven, we recognise the essential role of efficient and accurate quantity takeoffs (QTOs) in successful construction projects of all sizes. As a leading provider of construction consultancy services, we specialise in streamlining workflows and supporting informed decision-making throughout the project lifecycle.

Contact us today to discover how our solutions can increase the efficiency of your projects at the same time as providing the most cost-efficient solutions. Visit our services page to learn more about our comprehensive range of services.