The construction industry is undergoing a digital revolution in 2025, driven by advancements in technology that are reshaping how projects are designed, managed, and executed. The industry is no longer just about bricks and mortar, it’s about bytes, bots, and bold new possibilities. As cities grow and infrastructure demands soar, the need for smarter, faster, and more sustainable construction has never been more urgent. That’s where digital construction technology steps in.

Digital construction represents a paradigm shift in how we conceive, plan, build, and manage structures. With tools like Building Information Modelling (BIM), drones, digital twins, and AI-powered platforms, construction professionals are redefining the rules of the game. Projects that once took years now take months. What was once prone to error is now engineered for precision.

This article will unpack the major digital technologies reshaping construction in 2025. We’ll explore not only what they are, but how they work, what benefits they bring, and the challenges you need to prepare for. If you're a developer, contractor, architect, or policymaker looking to stay ahead, this is your guide to everything digital in the built environment.

What are the Examples of Digital Technologies in Construction?

Digital construction refers to the intelligent integration of digital tools and data-driven processes across every stage of a construction project, from initial concept and feasibility studies to construction execution, handover, and ongoing facility operations. It signifies a departure from siloed workflows and manual documentation toward a connected, transparent, and optimised environment. In 2025, the landscape of construction is shaped by a suite of powerful technologies that together redefine how the built environment is conceived and delivered.

Here are some of the most prominent digital technologies in construction today:

1. BIM (Building Information Modelling)

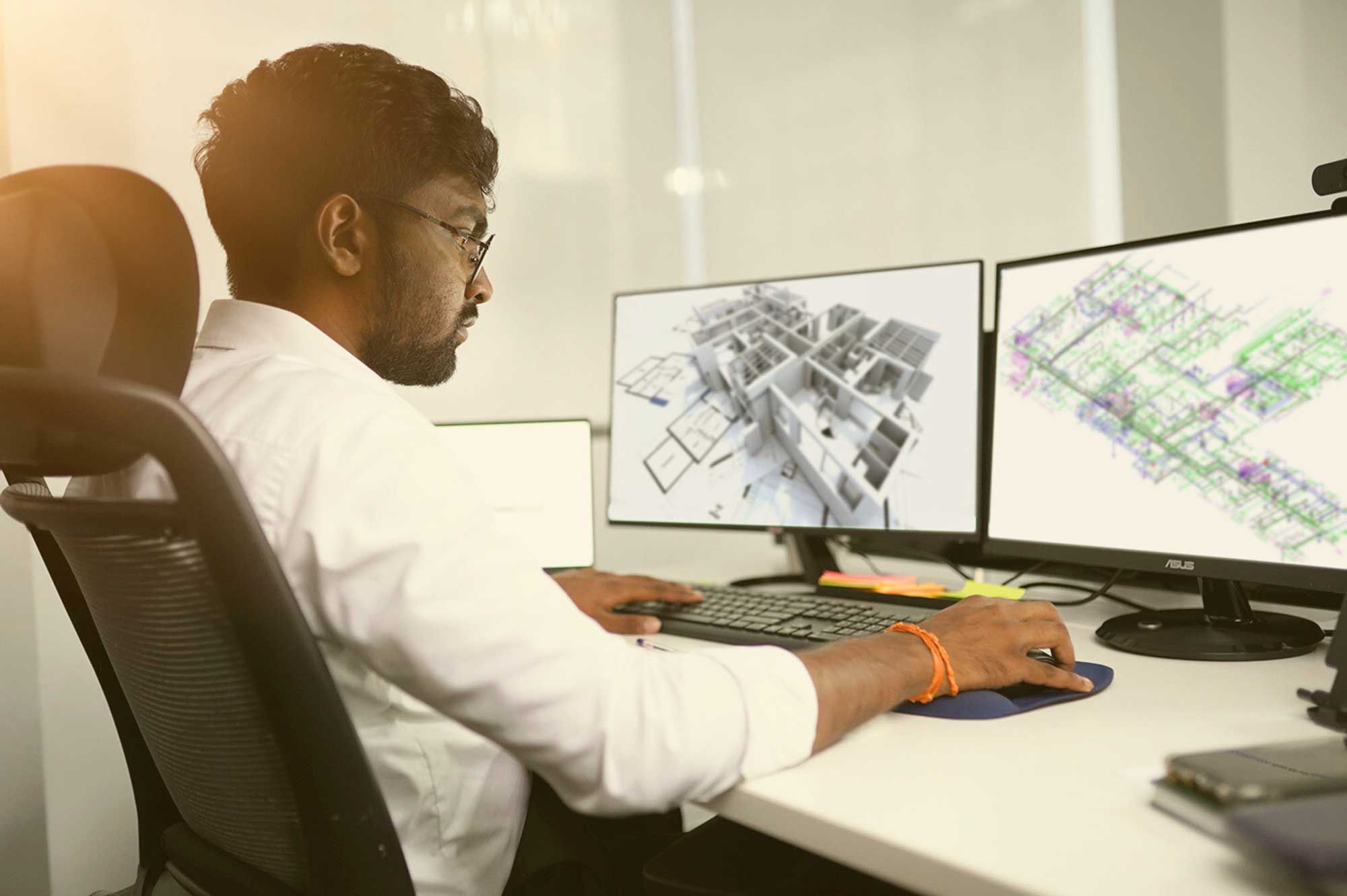

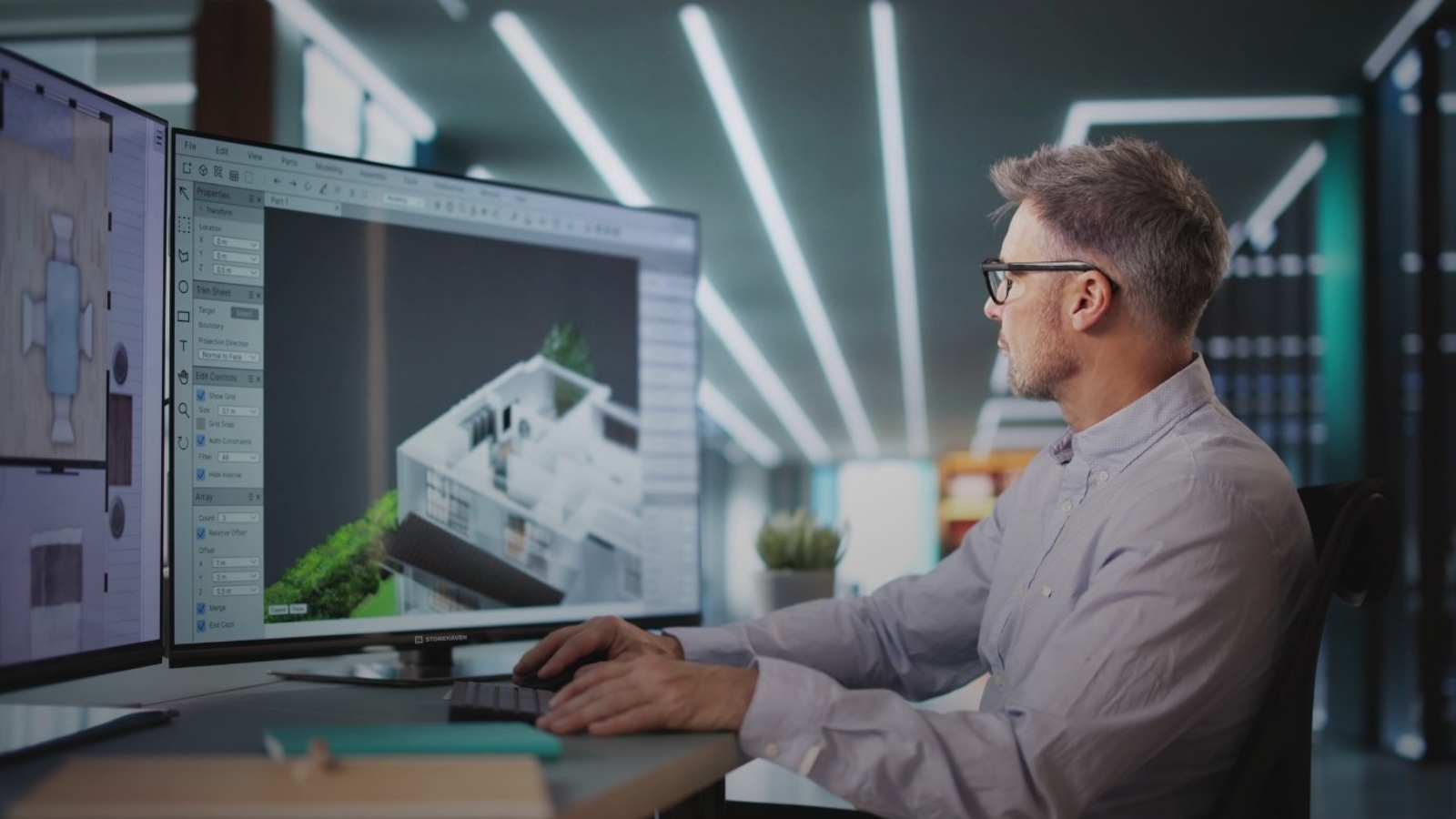

BIM is the cornerstone of digital construction. It enables architects, engineers, and contractors to collaborate using a shared digital model that represents the physical and functional attributes of a building. Beyond 3D modelling, modern BIM platforms incorporate 4D (time), 5D (cost), and even 6D (sustainability) data. This allows stakeholders to simulate construction schedules, estimate budgets, and plan for long-term maintenance, all before breaking ground.

By 2025, BIM adoption has become widespread, with 68% of architecture, engineering, and construction (AEC) professionals already using BIM in their projects. Among these adopters, 65% report that BIM delivers the highest return on investment (ROI) for their practice.

2. Drones

Unmanned Aerial Vehicles (UAVs), or drones, have become standard on construction sites. Equipped with high-resolution cameras and LiDAR sensors, drones capture aerial images and real-time data to monitor site progress, perform topographical surveys, and identify hazards. Compared to traditional surveying methods, drones reduce cost, time, and risk, making them essential for both pre-construction and ongoing oversight.

3. Digital Twins

A digital twin is a dynamic, data-driven replica of a physical asset. The digital twin market in construction is projected to grow at a compound annual growth rate (CAGR) of 17.03%, reaching $155.01 billion by 2030 from $64.86 billion in 2025. This growth is driven by the increasing integration of digital twins in resource management, safety monitoring, and predictive maintenance applications.

Unlike static models, digital twins are continuously updated using information from IoT sensors, maintenance records, and BIM data. This real-time synchronicity enables predictive maintenance, optimised performance, and lifecycle asset management. For large infrastructure and smart cities, digital twins offer strategic insights that were previously unimaginable.

4. AR/VR (Augmented and Virtual Reality)

AR and VR tools allow users to immerse themselves in the digital model of a structure before it is built. VR is widely used for client walkthroughs, safety training, and design validation, while AR overlays digital elements onto the physical world, helping workers visualise concealed systems like plumbing or electrical wiring. These technologies reduce miscommunication, accelerate approvals, and enhance stakeholder engagement.

5. IoT (Internet of Things) Devices

The Internet of Things in construction connects equipment, materials, and systems through embedded sensors. These devices track everything from temperature and humidity to machinery performance and worker movement. For example, smart concrete can report on curing conditions, while wearable tech can monitor worker fatigue. This constant stream of data supports real-time decision-making, preventive maintenance, and improved site safety.

6. AI and Machine Learning

Artificial intelligence is powering predictive analytics, risk management, and scheduling. AI can analyse vast datasets to detect patterns, flag potential delays, or optimise supply chains. Machine learning algorithms are used to forecast material needs, automate site logistics, and even design generative architecture layouts. The result: smarter decisions with fewer surprises.

As of 2025, 37% of construction businesses have adopted AI and machine learning technologies, up from 26% in 2023. This rapid growth reflects the industry's recognition of AI's potential to enhance efficiency and reduce costs.

7. 3D Printing

Additive manufacturing, or 3D printing, enables the creation of structural components (and even entire buildings) using materials like concrete or polymer composites. These elements can be prefabricated off-site or printed on-site to drastically reduce build times, material waste, and labour costs. 3D printing opens up design freedom and makes customised solutions more viable at scale.

8. Modular and Prefabricated Construction

Digitally enabled modular construction allows building components to be designed and fabricated in controlled factory environments before being assembled on-site. Digital clash detection ensures perfect alignment, while logistics are optimised using digital tools. This method increases quality, speeds up delivery, and reduces environmental impact, making it a key innovation in sustainable construction.

By combining these technologies, digital construction empowers project teams to build smarter, faster, and more collaboratively. It’s not just a matter of efficiency—digital construction redefines what is possible. It allows for holistic, end-to-end planning and execution that is proactive rather than reactive. Ultimately, this shift from analogue to digital is not a tech trend but a strategic transformation shaping the future of civil engineering, infrastructure development, and the entire built environment.

Digital Technology: Building Information Modelling (BIM)

Building Information Modelling (BIM) stands at the centre of the digital construction revolution. More than just a design tool, BIM is a process, a dynamic, data-rich ecosystem that enables the planning, design, construction, and management of buildings and infrastructure in a fully collaborative environment.

At its core, BIM allows stakeholders, architects, engineers, contractors, project managers, and facilities teams, to create, share, and update a unified digital model that reflects every physical and functional element of a built asset. From the foundation slab to the fire suppression systems, every detail is embedded with information, enabling transparency and traceability across the project lifecycle.

What BIM Enables:

● Architects can design and model complex structures in 3D, iterating quickly with better visualisation tools that support creativity and compliance.

● Structural and MEP Engineers can simulate the performance of systems like HVAC, plumbing, and electrical networks, testing everything from energy loads to pressure balance before construction even begins.

● Contractors and Builders can use 4D BIM (which incorporates time as the fourth dimension) to plan construction sequencing, improve logistics, and coordinate subcontractors more efficiently.

● Cost Managers can leverage 5D BIM to automatically extract quantities and generate real-time cost estimates, reducing the risk of budget overruns.

● Facility Managers can access a 6D BIM model post-construction, which includes lifecycle data for asset tracking, preventive maintenance scheduling, and retrofitting.

Why BIM is Needed in the AEC Industry

Traditional construction often suffers from fragmented workflows and miscommunication between disciplines. Architects, engineers, and contractors may work from separate documents, leading to conflicting information, duplication of effort, and costly errors.

BIM solves this by becoming a single source of truth. Everyone involved in the project refers to the same intelligent model. Any updates made by one team member, say, a change to the structural framework, are instantly reflected across the board. This interoperability reduces misalignment, eliminates rework, and dramatically shortens approval times.

Moreover, BIM's clash detection capabilities allow engineers to identify spatial conflicts, such as ductwork intersecting with a beam, before they reach the construction site. This proactive approach improves buildability and ensures that designs are practical, safe, and cost-efficient.

Digital Technology: Construction Drones

Drones are a mainstay on construction sites, offering a fast, cost-effective, and highly accurate way to capture site data and visual documentation. These Unmanned Aerial Vehicles (UAVs) have evolved from niche tech to essential tools that deliver real-time insights across the entire construction lifecycle. They’re no longer a luxury add-on, they’re a necessity for companies aiming to stay competitive in a digital-first industry.

Aerial surveys using drones are now standard practice. Equipped with high-resolution cameras or LiDAR sensors, drones can map large areas in a fraction of the time it takes using manual methods. This data feeds directly into BIM systems or GIS platforms, allowing project teams to assess terrain conditions, calculate earthwork volumes, and plan logistics more effectively from day one. The accuracy and frequency of this data also help reduce design changes and errors later in the build.

Beyond surveying, drones excel at progress monitoring and safety inspections. Routine flyovers can be programmed to capture consistent angles, offering visual timelines that help managers assess work completed, spot delays, or detect quality issues. When fitted with thermal or infrared sensors, drones can also flag overheating machinery or insulation failures. Most importantly, they remove the need for human workers to inspect risky or elevated areas, drastically improving on-site safety.

By enabling predictive maintenance, enhancing visibility, and improving documentation for stakeholders, drones are transforming construction management into a proactive discipline. Combined with cloud platforms and AI-based analysis, the data drones collect is helping teams make smarter, faster decisions, while keeping costs and risks in check. In short, drones are now as critical to a project’s success as cranes or concrete.

Digital Technology: Digital Twins

Digital twins are redefining how we understand, manage, and optimise the built environment. A digital twin is a real-time, data-driven replica of a physical asset, be it a building, a bridge, or an entire urban district. Linked with IoT sensors, cloud platforms, and AI algorithms, digital twins continuously update to reflect changes in usage, performance, and condition. This isn't just about visualisation, it's about insight, prediction, and control.

During the construction phase, digital twins allow teams to simulate workflows, test various build sequences, and identify potential inefficiencies before they occur on-site. This proactive approach reduces delays and ensures that construction follows the most logical, cost-effective path. After project handover, the twin doesn't disappear, it transitions into a powerful facilities management tool. It tracks wear and tear, monitors systems like HVAC and lighting, and alerts operators to maintenance needs before breakdowns occur.

What sets digital twins apart in 2025 is their widespread application across both vertical and horizontal infrastructure. They're being deployed not just in skyscrapers, but also in roads, airports, hospitals, ports, and even smart city developments. For instance, a digital twin of a metro line might monitor passenger flow, energy usage, and rail integrity in real time. With AI integration, these models can simulate future scenarios, such as predicting how a building will respond to extreme weather or how traffic patterns will change after a new development is introduced.

Ultimately, digital twins represent a significant shift from reactive to predictive asset management. They create a continuous feedback loop between the physical and digital realms, empowering owners and operators to make data-driven decisions throughout an asset’s entire lifecycle. From reducing energy consumption to extending the lifespan of critical infrastructure, digital twins are helping the construction industry build not only smarter, but also more resilient and sustainable systems.

What Are the Best Practices for Digital Construction Management?

As digital tools reshape the construction landscape, successful adoption hinges not just on technology itself, but on how well it's managed. Digital construction isn’t a one-off upgrade, it’s an ongoing transformation that demands strategic foresight, skilled teams, and robust governance. Without the right framework, even the best technologies can fall short of delivering value. Here are the most effective best practices to ensure digital construction management leads to measurable success:

1. Strategic Planning

Before investing in new technology, companies must clearly define their goals. What problems are you trying to solve? Are you looking to improve cost estimation, project scheduling, or site safety? Once objectives are set, identify Key Performance Indicators (KPIs) to track impact. Avoid adopting tools simply because they’re trending; instead, choose platforms that align with your specific project scope, budget, and timeline. A well-structured digital roadmap helps minimise unnecessary spending and maximises ROI.

2. Cross-Team Collaboration

Digital tools thrive when used collaboratively. Encourage architects, engineers, contractors, and consultants to work within shared platforms like Autodesk BIM 360, Procore, or Revizto. These tools foster transparent communication, streamline workflows, and enable real-time access to updated project data. Unified systems reduce the risk of miscommunication and significantly cut down on errors, change orders, and costly rework.

3. Training and Upskilling

The success of any digital initiative depends on the people behind it. Equip your team with the skills needed to fully leverage new tools through regular training, certification programmes, and hands-on workshops. Include both technical education (e.g., BIM modelling, drone data analysis) and soft skills like data interpretation and digital collaboration. Empowering your workforce ensures they remain confident and competent as systems evolve.

4. Iterate and Improve

Digital transformation doesn’t end after implementation. Schedule regular project reviews to assess which tools are delivering results and which need improvement. Collect feedback from across the project hierarchy, from site workers to project directors, and use it to refine your project strategy. Encourage a culture of experimentation and adaptability. By treating digital construction as an evolving process, companies can stay ahead of the curve and continuously improve performance.

Conclusion

2025 is not the future, it is now. Digital construction has arrived, and it's reshaping the industry from foundation to finish. Those who embrace this transformation will lead the next generation of building excellence, while those who lag behind risk being left out of the conversation.

From the precision of BIM to the insights of digital twins and the reach of drones, every new technology adds a layer of intelligence to our infrastructure. Digital construction isn’t just about tech for tech’s sake. It’s about building better, smarter, and more sustainably, for people, profit, and the planet.

About us

At Stonehaven, we are redefining how construction happens in the Middle East. As a premier provider of digital construction solutions, we partner with developers, architects, and contractors to turn bold visions into precise, efficient realities. From high-rise towers in Dubai to infrastructure upgrades in Riyadh, our work is grounded in a deep understanding of regional demands and a forward-thinking embrace of global innovation.

Our expertise spans the full spectrum of digital construction, including advanced BIM modelling and coordination, drone-based mapping and real-time progress reporting, and the implementation of intelligent digital twins for lifecycle asset management. We also offer strategic consulting on construction technology integration and deliver actionable insights through project data analytics and reporting.

What sets Stonehaven apart is not just the technology we bring to the table, but the insight behind it. Every solution we implement is tailored to add tangible value across the entire project lifecycle—boosting productivity, improving safety, and ensuring sustainability.

Whether you're launching a megaproject or optimising an existing asset, we are your partner in progress. Discover how Stonehaven can help you embrace the future of construction.

Let’s build the future, with digital support.