EPC, short for Engineering, Procurement, and Construction is a contract-based project delivery model that has revolutionised how large-scale developments are executed, particularly in sectors such as energy, oil and gas, utilities, and infrastructure.

Whether you’re navigating a multi-million-pound power plant or building a commercial structure in the UAE, EPC contractors streamline complex undertakings by managing every phase of construction from concept to commissioning. In a world that increasingly prioritises efficiency, accountability, and time-to-market, the rise of Engineering Procurement and Construction (EPC) Services is far from coincidental.

Whether you're a project owner, investor, or contractor, understanding how EPC companies in the UAE and beyond operate and how their services differ from other contracting models is essential for informed decision-making.

With in-depth insights, industry-relevant comparisons, and key considerations for choosing an EPC provider, this guide is your comprehensive resource to understanding EPC contracts, EPC projects, and why they matter now more than ever.

What is EPC?

EPC which stands for Engineering, Procurement, and Construction, is a form of project delivery arrangement in which a single contractor is responsible for the design, procurement of materials, and construction of a project. This turnkey approach shifts accountability to the EPC contractor, offering the client a simplified, hands-off process with a fixed cost and schedule.

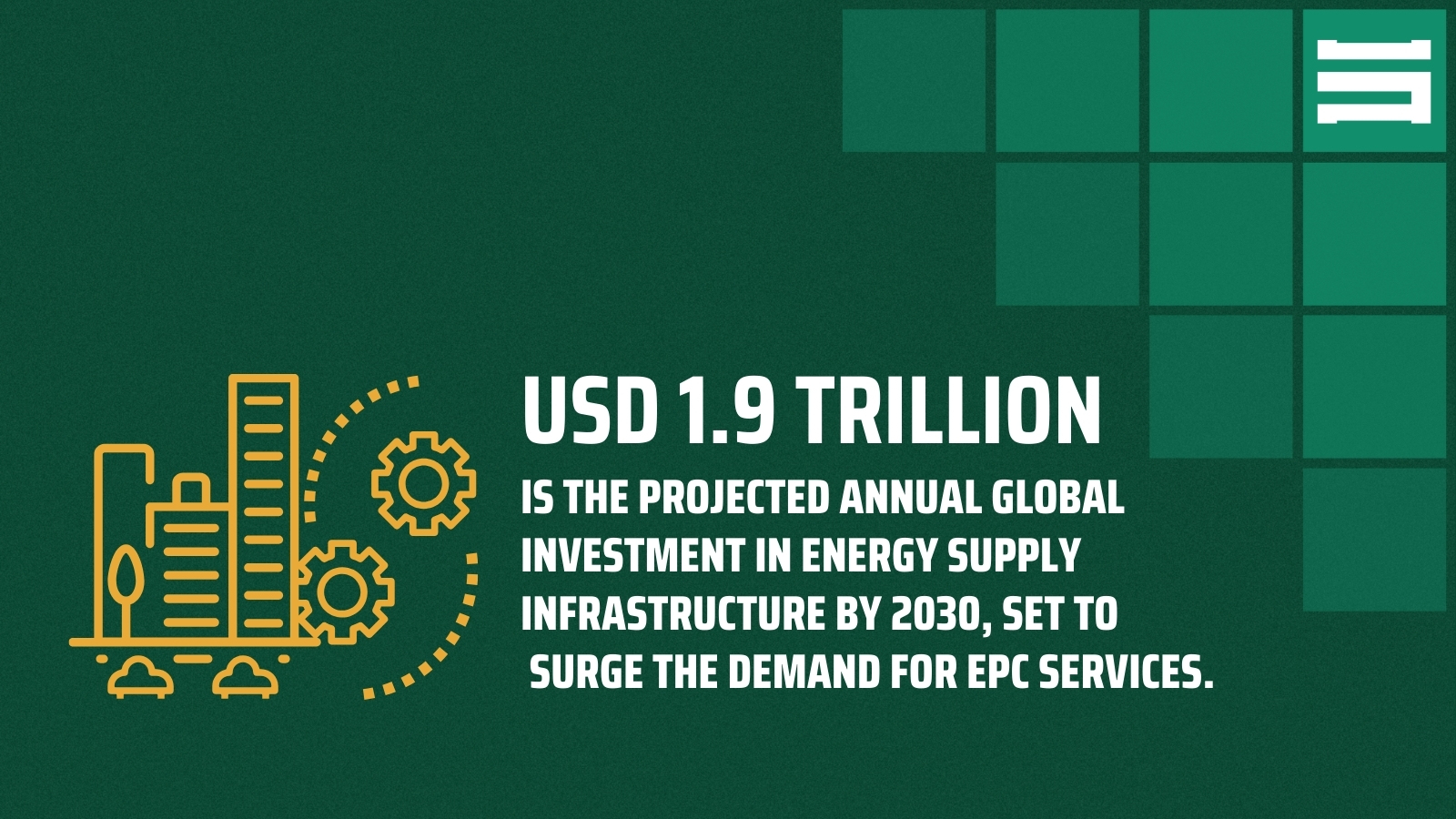

As nations accelerate investment in infrastructure and clean energy, the demand for end-to-end, turnkey solutions continues to rise. It is reported that global investment in energy supply infrastructure is projected to reach USD 1.9 trillion annually by 2030. This surge in spending creates a massive need for EPC consulting and construction services across increasingly complex projects.

What differentiates EPC from traditional models is the degree of integration. Rather than engaging separate contracts for design, material sourcing, and construction, EPC consolidates all aspects under a single entity. This structure is particularly beneficial in high-stakes environments like oil refineries, energy plants, and industrial developments, where synchronisation across stages is critical.

In the UAE, where speed of development and precision engineering are cornerstones of economic growth, EPC companies provide a trusted mechanism to execute intricate projects efficiently. A well-structured engineering procurement and construction contract solves potential risk, ensures cost control, and enhances project predictability.

Moreover, EPC contractors typically guarantee performance metrics, making them particularly attractive for owners looking to achieve operational output from day one. By the end of an EPC project, the facility or infrastructure is fully operational, tested, and handed over — essentially ready for use.

What is the Engineering, Procurement and Construction Process?

The EPC process is methodical, sequential, and anchored in precision. It consists of three core phases, each representing a vital function in delivering complex construction and infrastructure projects.

1. Engineering

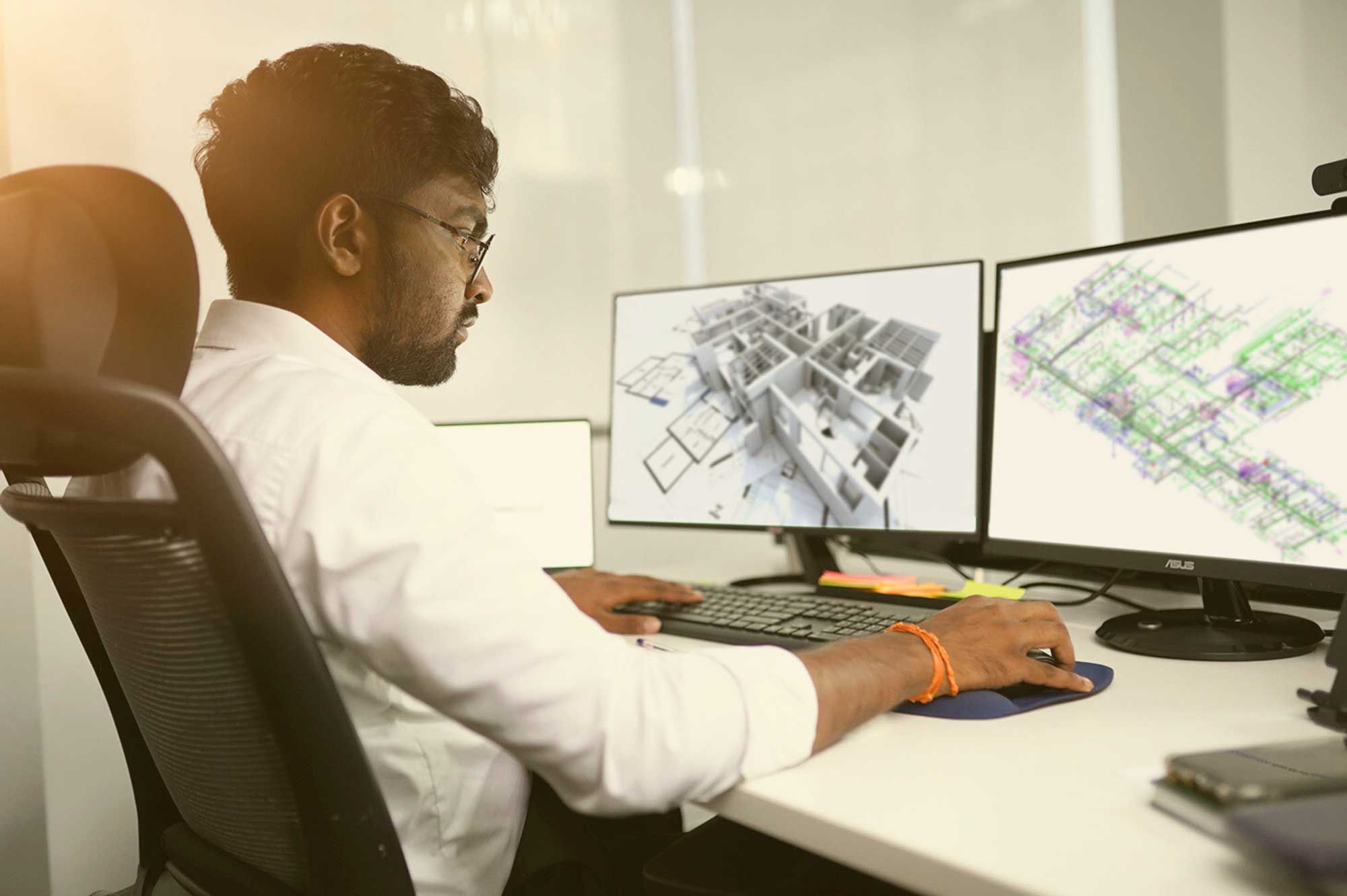

This stage includes the complete design and planning of the project. Detailed specifications are developed through feasibility studies, geotechnical analysis, architectural planning, and systems engineering. The EPC contractor translates client requirements into a functional blueprint, ensuring that the resulting designs are viable, efficient, and compliant with regulatory norms.

Engineering also sets the straight foundation for accurate cost estimates and timelines, two major metrics in any EPC contract.

2. Procurement

Once the engineering is approved, the procurement phase kicks in. This involves sourcing all required materials, equipment, and services necessary for the project. EPC contractors often leverage a vast supplier network to secure competitive pricing, quality assurance, and timely deliveries. It is here that the global reach of EPC companies in the UAE becomes apparent, with firms sourcing from multiple international vendors.

Key activities during this phase include issuing purchase orders, managing supply chains, and handling logistics.

3. Construction

Finally, with design in hand and materials in place, construction begins. The EPC contractor manages the entire on-site process from labour and subcontractors to health and safety compliance. What sets this apart is the integrated nature of the operation. Engineering insights feed directly into the construction process, and procurement timelines are synchronised with build schedules.

Once construction is complete, the facility undergoes testing and commissioning to ensure it meets all agreed-upon performance standards. The client receives a "ready-to-operate" asset, the hallmark of epc construction excellence.

What are the Main Differences Between EPC and DBB?

To understand the value of EPC, it's helpful to compare it with the Design-Bid-Build (DBB) model, one of the most traditional methods in the construction industry.

Design-Bid-Build (DBB)

Under DBB, the project owner contracts separately with designers and builders. The process unfolds linearly: first, architects and engineers design the project; then, construction companies bid to build it based on those designs. While this offers the owner significant control over design, it often leads to coordination challenges, cost overruns, and extended timelines.

In DBB, accountability is fragmented. If issues arise during construction due to design flaws, disputes often erupt over who is responsible, the designer or the builder.

Engineering, Procurement, and Construction (EPC)

In contrast, EPC contracts integrate all phases under a single contract. The EPC contractor assumes complete responsibility for the design, procurement, and construction. This means fewer coordination issues, quicker turnaround, and a fixed price which minimises the risk of cost escalation.

EPC is very outcome focused. The contractor guarantees not just completion, but operational performance, a critical distinction for infrastructure projects where the end goal isn’t just building something, but making it work reliably.

In markets like the UAE, where time, cost, and operational readiness are paramount, epc companies are often preferred over DBB firms for major infrastructure and industrial developments.

What are the Main Differences Between EPC and LSTK?

Another comparison frequently made is between EPC and LSTK (Lump Sum Turnkey) contracts. At first glance, these models appear similar and indeed, there is significant overlap. However, nuanced differences exist.

Lump Sum Turnkey (LSTK)

LSTK contracts are a type of fixed-price agreement where the contractor delivers the completed facility at a pre-agreed lump sum. It’s the contractor’s job to handle all aspects of design and construction, handing over a fully operational asset, hence the term "turnkey".

Risk is squarely on the contractor. If unforeseen issues arise or costs increase, the contractor absorbs the impact, not the project owner.

EPC

EPC contracts are often structured similarly but allow for more flexibility in terms of procurement strategies and project management. While an EPC contract can also be lump sum, it may include cost-plus components or milestone-based payments depending on project complexity.

Where LSTK emphasises price certainty, EPC contracts focus on project integration. EPC contractors often bring specialised engineering and procurement expertise in-house, streamlining timelines and reducing dependencies on third-party vendors.

In practice, many EPC projects particularly in the UAE, are delivered under an LSTK structure. However, not all LSTK projects are EPC. Understanding this nuance is crucial when evaluating epc companies in the UAE, as their contract model may impact risk allocation, payment schedules, and project flexibility.

How are EPC Contracts used in large-scale projects?

EPC contracts are the backbone of some of the world’s most ambitious infrastructure projects, especially where complexity, scale, and coordination are non-negotiable.

In the energy sector, EPC models dominate power plant developments from solar farms to combined-cycle gas turbines. These projects require a seamless integration of engineering precision, technology procurement, and rigorous construction timelines.

In oil and gas, EPC contractors are tasked with developing refineries, processing units, and storage facilities. These high-stakes environments demand rigorous compliance, operational safety, and performance guarantees all hallmarks of EPC delivery.

The UAE has become a global hub for EPC-driven developments. From desalination plants in Abu Dhabi to industrial free zones in Dubai, epc companies in the UAE offer specialised services tailored for the region’s economic and regulatory landscape. Their ability to deliver complex projects on time and within budget has made them invaluable partners for both government and private investors.

Moreover, with the rise of green energy initiatives, EPC models are increasingly used in solar and wind projects where modular design, quick commissioning, and return on investment are key.

Ultimately, the value of an epc contractor lies in their ability to translate vision into reality, managing the myriad moving parts of a large-scale build while offering the client peace of mind through single-point accountability.

How Do You Ensure an Effective EPC Contract?

For an EPC contract to be effective, clarity, accountability, and enforceability must be embedded in its structure. Whether you’re engaging EPC companies in the UAE or abroad, here are key elements to secure:

1. Define Your Scope Clearly

The contract should explicitly define the scope of work — including engineering deliverables, procurement timelines, and construction milestones. Vague definitions often lead to disputes, delays, and cost variations.

2. Guarantee Performance Targets

A cornerstone of any epc contract is the guarantee of operational performance. This might include output thresholds, safety standards, or commissioning targets. Penalties or liquidated damages should be tied to underperformance.

3. Incorporate Payment Terms

Clarify payment structures whether lump sum, milestone-based, or performance-linked. Ensure that terms are aligned with cash flow planning and risk exposure.

4. Change Order Protocol

Changes during project execution are inevitable. The contract must outline how these are to be evaluated, approved, and priced, ensuring transparency and avoiding scope creep.

5. Account for Risks

Assigning risk appropriately is essential. Weather delays, material cost escalation, and regulatory changes should be accounted for with fair and balanced clauses.

6. Include Dispute Resolution Methods

Include mechanisms such as mediation or arbitration clauses to address conflicts swiftly without disrupting project timelines.

A well-drafted engineering procurement and construction contract protects both parties, enabling trust, transparency, and timely delivery as EPC becomes the default model for mega projects.

Conclusion

As the built environment grows more complex and interconnected, EPC construction continues to emerge as a reliable, efficient, and scalable solution for delivering projects of all kinds from utility infrastructure to industrial facilities.

By consolidating responsibility under a single epc contractor, clients can really reduce fragmentation, reduce risk, and ensure performance from day one. This model is especially valuable in regions like the UAE, where accelerated development timelines and technical precision are paramount.

But beyond its logistical advantages, EPC represents a philosophical shift in how we approach large-scale construction: from transactional, disjointed engagements to holistic, results-driven partnerships.

Understanding the nuances between EPC and other models whether DBB or LSTK can empower stakeholders to make informed, strategic decisions. It’s not just about cost, but control, accountability, and certainty.

For developers, investors, and project owners seeking long-term value and operational assurance, choosing the right EPC partner is more than a procurement decision.

About us

At Stonehaven, we believe that every structure tells a story and as one of the leading EPC companies in the UAE, we bring vision, engineering excellence, and executional rigour to every engagement.

From concept to commissioning, we offer comprehensive Engineering Procurement Construction (EPC) Services catered to a wide range of industries including energy, infrastructure, industrial manufacturing, and sustainable development.

Why Choose Stonehaven?

-

End-to-End Expertise: Our integrated approach ensures coordination across all project phases. reducing delays, controlling costs, and maintaining quality.

-

Regional Understanding: With deep insights into the regulatory, environmental, and economic landscapes of the Middle East, we adapt global standards to local realities.

-

Performance Focused: We don’t just build; we deliver outcomes. Every EPC project we undertake is backed by performance guarantees and tested commissioning.

-

Customised Contracting: We offer a flexible approach to types of EPC contracts, ensuring the right fit for every client’s risk profile and delivery goals.

Partner with Stonehaven for precision to meet performance, and for your EPC projects to become milestones.