In the ever-evolving world of construction, where skyline-defining towers rise in months and megaprojects span across deserts and coastlines, one element remains quietly foundational—reinforcement. It’s not the material you see, but it’s the material that saves lives, carries the weight of architecture, and transforms brittle concrete into something almost heroic.

Without reinforcement, concrete would be nothing more than a compressive block. Strong, yes—but limited. Tension, bending, shear, environmental strain, these are challenges that plain concrete can’t bear alone. That’s where reinforcement steps in. Reinforcement in concrete construction is what allows buildings to defy gravity, absorb seismic shock, endure decades of stress, and still stand tall.

This article will explore the essential types and applications of reinforcement in construction engineering. Whether you’re a site manager refining detailing for a new flyover, an architect designing slender slabs, this guide covers the full spectrum. From pre-stressed concrete on infrastructure megaprojects to the use of steel reinforcement in residential slabs, we’ll unpack it all.

What is the Function of Reinforcement in Concrete Structures?

Reinforcement fundamentally transforms concrete from a brittle material into a resilient, load-bearing backbone capable of withstanding bending, tension, shear, and environmental stresses. In 2024, the global concrete materials market, encompassing both reinforced and non-reinforced types, was valued at approximately USD 312 billion, and is projected to exceed USD 321.5 billion in 2025, growing at about 3 % annually. Within this, the reinforcing steels market alone reached USD 280.2 billion in 2024 and is on track to hit USD 293.4 billion in 2025, with a steady 4.7 % CAGR.

Concrete is highly capable of resisting compressive forces, ideal for supporting vertical loads. However, under tensile stress, such as bending, its performance drops dramatically, often resulting in cracks or structural failure. Reinforcement bridges this weakness by introducing steel or fibre elements that carry tensile loads, enhancing overall durability and structural integrity.

Steel’s tensile strength and thermal compatibility make it the go-to reinforcement material. When combined:

● Concrete takes compressive load

● Steel counters tensile and shear stress

Together, they behave as a unified composite system, distributing stress effectively and reducing the risk of catastrophic failure.

The fiber reinforced concrete (FRC) market was valued at about USD 2.53 billion in 2024 and is projected to grow to USD 2.86 billion by 2025, a sign that materials enhancing crack control and impact resistance are in rising demand.

These market trends illustrate a clear global shift toward structural systems enriched with tensile-strengtheners, underscoring the consistent importance of reinforcement in modern construction. This shift isn't just economic; it reflects a deeper engineering priority: ensuring that concrete structures are not only strong but adaptable, durable, and safe under diverse conditions.

Reinforcement adds critical functional value. It strengthens concrete against bending and twisting, enabling beams and slabs to withstand live loads and dynamic stresses without compromising structural integrity. It also improves ductility, allowing buildings to flex and dissipate energy during seismic activity, a vital characteristic in earthquake-prone regions.

Moreover, reinforcement plays a crucial role in controlling crack propagation. By limiting crack widths and patterns, it preserves the structure’s integrity and protects against water ingress or chemical exposure. In harsh climates, especially in coastal or industrial zones, reinforcement enhances environmental durability by reducing vulnerability to moisture, corrosion, and thermal stress.

From load-bearing columns and cantilever slabs to tunnels and bridge decks, reinforcement acts as the structural DNA of concrete, quietly ensuring resilience, longevity, and performance at every level.

Why Is It Important to Reinforce a Structure?

The importance of reinforcement in construction cannot be overstated. It is the engineering mechanism that transforms concrete from a basic compressive material into a versatile, high-performance structural solution. Reinforcement enhances the structural integrity of concrete, allowing it to perform well under tension, bending, shear, and dynamic loads, conditions that most modern structures face on a daily basis.

At the heart of reinforcement lies structural safety. Reinforced concrete can absorb and distribute loads caused by wind, seismic activity, vehicular traffic, and vibrations, factors that frequently challenge the stability of bridges, tunnels, flyovers, and high-rise buildings. Without reinforcement, these forces would lead to cracks, instability, and potential collapse. In fact, global seismic design codes, such as Eurocode 8 and ACI 318, mandate specific reinforcement detailing precisely for this reason.

Beyond immediate stability, reinforcement contributes to long-term durability. It delays material fatigue and combats degradation caused by repeated loading, moisture ingress, and temperature shifts. By absorbing internal stress before cracks develop or propagate, reinforcement extends the life span of buildings and infrastructure, reducing the need for early repairs or retrofitting. This translates to lower lifecycle maintenance costs, a crucial factor in large-scale infrastructure planning.

Reinforcement also unlocks design freedom. Structural elements such as thin floor slabs, long cantilevered balconies, and curvilinear facades become possible only through strategic reinforcement. This enables architects and engineers to push aesthetic and functional boundaries without compromising on safety.

From an economic standpoint, reinforcement improves material efficiency. Stronger, thinner components can be designed with less concrete, reducing volume and dead weight while retaining strength. This not only optimises material use but also lowers transport, labour, and formwork costs, an advantage that scales dramatically across large projects.

In hostile environments, such as the Gulf region, where extreme heat, dust storms, and saline groundwater are common, reinforcement is essential. Corrosion-resistant rebar, post-tensioned cables, and protective detailing ensure concrete doesn’t degrade prematurely, preserving structural integrity in desert climates.

Simply put, unreinforced concrete is no match for the demands of modern construction. Reinforcement is what makes civil engineering viable, scalable, and sustainable in a world that expects buildings to be not just functional, but future-proof.

What are the Types of Reinforcement?

The type of reinforcement selected in a construction project often depends on factors such as load requirements, environmental conditions, budget constraints, and design specifications. The most common types include:

1. Steel Reinforcement (Rebar)

This is the most widely used form. Steel is ideal because it bonds well with concrete, has similar thermal expansion properties, and provides high tensile strength. It comes in various grades and diameters, and can be ribbed or smooth.

2. Welded Wire Fabric (WWF)

Often used in slabs and pavements, welded wire reinforcement consists of a grid of steel wires pre-welded at intersections. It’s easy to install and efficient for distributing shrinkage cracks.

3. Fibre Reinforcement

Fibres made of steel, polypropylene, or glass are mixed into the concrete. Though not as structurally strong as rebar, they help control microcracking and increase impact resistance.

4. Pre-stressed and Post-tensioned Reinforcement

Used primarily in large infrastructure projects, pre-stressed concrete is reinforced before concrete is cast. In contrast, post-tensioned concrete has tensioning cables that are stressed after the concrete cures. These techniques are commonly found in bridges, parking garages, and long-span floor systems.

5. Epoxy-Coated or Galvanized Reinforcement

In corrosive environments, like coastal cities or wastewater treatment plants, steel is coated with epoxy or galvanised to prevent rusting and deterioration.

Each type serves specific structural needs, and the correct selection plays a pivotal role in the safety, efficiency, and life span of the building or structure.

What are the Specific Aims of Detailing in a Structure?

Reinforcement detailing refers to the precise documentation and placement of rebars within a concrete structure. Far from just a technical drawing, detailing is a critical phase of structural design that bridges concept and construction.

Key aims of detailing include:

● Clarity of Communication: Detailing communicates exact specifications to site engineers, contractors, and building construction companies, preventing costly errors or unsafe practices.

● Structural Efficiency: Proper detailing ensures that rebars are placed where they’re most needed, optimising material use and reducing waste.

● Compliance: Detailing must adhere to local codes and safety regulations. This is especially important for infrastructure projects governed by strict public safety codes.

● Durability: Accurate detailing specifies clear cover, the protective layer of concrete around reinforcement bars, which shields against corrosion, moisture, and fire.

● Bond and Anchorage: It ensures that reinforcements are adequately embedded and overlapped to maintain structural continuity and load transfer.

● Constructability: Poor detailing leads to congestion, difficulty in placement, or clashes with formwork. Good detailing balances strength with ease of execution.

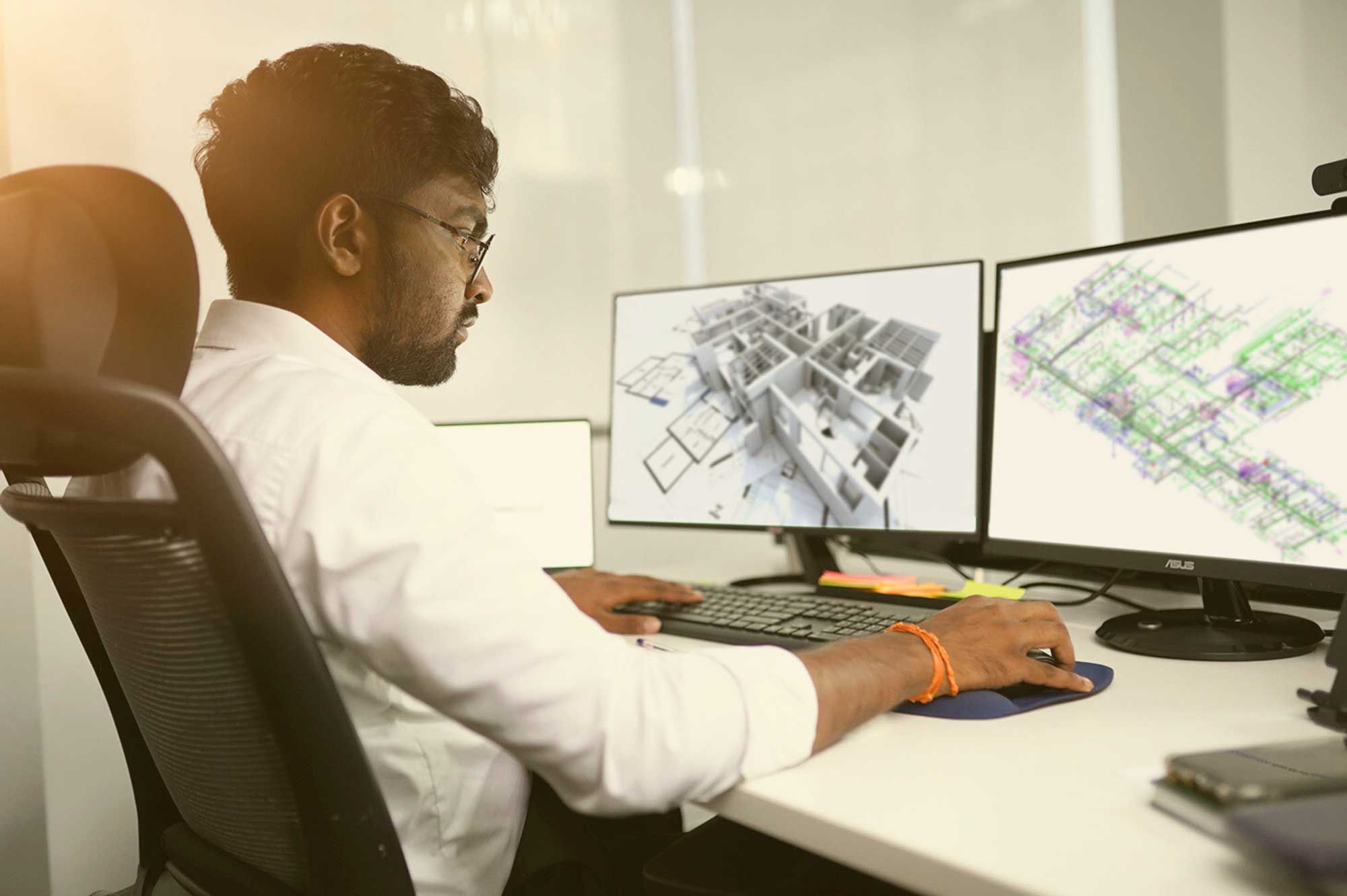

In digital construction workflows, reinforcement detailing is increasingly handled using BIM (Building Information Modelling), which allows 3D visualisation, clash detection, and coordination across teams. This ensures faster approvals, better project management, and safer structures on the ground.

How Does Reinforcement Detailing Affect Bond and Load Transfer?

Reinforcement in concrete works not by magic, but by physics, and bond is the secret ingredient. Bond is the adhesive-like grip between steel and concrete that ensures the two materials act as a single unit. This bond allows the transfer of loads (tension, compression, shear) from the concrete to the steel reinforcement and vice versa.

Detrimental detailing can compromise this vital interaction.

Key considerations:

● Proper Anchorage Lengths: The rebar must be embedded deep enough into the concrete so that it doesn’t slip under load. Shortcuts here can lead to sudden structural failure.

● Overlap Splicing: When two rebars are joined, they must overlap sufficiently for effective load transfer. Inadequate overlaps weaken structural continuity.

● Bar Bending and Hooking: Hooks, bends, and stirrups are added not only to prevent slipping but to improve confinement and crack resistance, particularly in seismic zones.

● Concrete Cover: Adequate clear cover shields reinforcement from moisture, temperature, and fire. If detailing overlooks cover, bond integrity deteriorates rapidly, especially in aggressive environments.

● Surface Texture of Bars: Deformed bars with ribs grip concrete better than smooth bars. Detailing ensures the right bar type is selected and correctly oriented.

Incorrect or incomplete detailing reduces bond strength and results in structures that underperform or fail catastrophically. In regions known for mega infrastructure projects, like the UAE, bond failure can mean delays, lawsuits, or worse.

What Are the Common Challenges in Reinforcement in Construction?

Even with high-quality materials and precise design, reinforcement in construction presents several practical challenges that can impact project outcomes. From execution on-site to digital coordination, these issues require careful management to ensure structural integrity and efficiency.

1. Congested Reinforcement: In dense structural zones, like bridge piers or deep foundations, excessive reinforcement can lead to congestion. This makes concrete placement and compaction difficult, increasing the risk of voids or honeycombing. Clear detailing and strategic bar spacing are essential to avoid structural weakness.

2. Corrosion: Steel reinforcement is prone to rust when exposed to moisture and air, particularly in coastal or high-salinity areas. Corrosion causes expansion, leading to cracking and spalling in concrete. Protective measures such as adequate clear cover, epoxy coatings, or corrosion inhibitors are necessary in harsh environments.

3. Human Error: Manual installation of reinforcement remains vulnerable to mistakes, incorrect bar placement, insufficient overlaps, or misaligned hooks can compromise structural performance. Regular supervision, clear bar schedules, and on-site training help reduce rework and safety risks.

4. Procurement Delays: Specialised reinforcement materials, such as high-strength steel or post-tensioned systems, may have long lead times. Delays in procurement can disrupt construction timelines, especially if coordination with suppliers and contractors is lacking.

5. BIM and Software Gaps: Although BIM enhances detailing and coordination, adoption remains slow among smaller contractors due to cost and skill gaps. Without digital integration, errors can arise between design and execution.

6. Labour Shortages: Skilled rebar fixers are in short supply across many regions, leading to slower progress and inconsistent quality. Expanding vocational training in reinforcement techniques is vital to meet growing industry demand.

To the untrained eye, reinforcement might seem straightforward. In reality, it’s a delicate science, one where small mistakes can have significant structural consequences.

How Can You Reinforce Existing Structures?

Reinforcement isn’t just for new buildings. Retrofitting and strengthening existing structures is becoming increasingly critical in construction, especially for ageing infrastructure or buildings needing code upgrades.

Common methods include:

● External Steel Plate Bonding: Steel plates are bonded to beams or slabs using epoxy adhesives. These provide additional tensile strength without major alterations.

● FRP Wrapping (Fibre-Reinforced Polymers): Lightweight, corrosion-resistant, and easy to install, FRPs are used to wrap columns and beams, especially in seismic retrofits.

● Jacketing: Enlarging columns or beams with additional reinforcement and concrete is common in load-bearing upgrades.

● Post-tensioning: Adding tensioned cables after construction to improve flexural capacity.

● Epoxy Injection: For crack repair and minor strengthening.

Before selecting a method, engineers conduct structural audits using tools like ground-penetrating radar (GPR), ultrasonic pulse velocity, or load testing. In cities rapidly modernising their building stock, like Riyadh, Doha, or Abu Dhabi, retrofitting becomes a cost-effective and sustainable solution.

Conclusion

Reinforcement is not just a technical requirement, it’s a cornerstone of modern engineering. Without it, the concrete jungle we live in would collapse under its own weight. From steel rebar in a residential column to post-tensioned cables in megaprojects, reinforcement is what allows creativity, safety, and sustainability to coexist in construction.

As construction companies in the Middle East race to meet urbanisation goals and green building standards, intelligent reinforcement design will separate efficient builds from liabilities. Whether you're on a construction site, drafting plans at a design consultancy, or managing a government contract, understanding the intricacies of reinforcement is crucial.

The next time you pass a flyover or walk into a high-rise lobby, remember: it’s not just the concrete you see, it’s the reinforcement beneath it that makes it all possible.

About us

Stonehaven is a leading construction cost consultancy based in the UAE, trusted by developers and contractor companies across the GCC. We specialise in providing expert guidance on reinforcement design, detailing, and cost planning for projects of all scales, from high-rise towers in Dubai to large-scale infrastructure upgrades in Sharjah.

Our strength lies in combining technical precision with a deep understanding of local regulations and market dynamics. We work closely with clients to align reinforcement strategies with structural performance goals, sustainability targets, and budget constraints. Whether you’re navigating the complexities of steel procurement, exploring post-tensioned concrete solutions, or seeking to streamline rebar detailing, our team delivers cost-effective and compliant solutions at every stage of the construction process.

Stonehaven integrates advanced digital tools such as BIM into our workflows, ensuring that every aspect of reinforcement design is coordinated, accurate, and construction-ready. We also support lifecycle cost assessments and material take-offs, helping you optimise procurement strategies and minimise waste.

Our engineers are not just advisors, they are collaborators, committed to delivering value from concept to execution. From early feasibility studies to retrofit audits, we provide the insight and support needed to ensure your reinforced concrete systems perform as designed and stand the test of time.