Quantity take-offs are the process of itemising and quantifying every material required for a project, and form the bedrock of cost estimation, procurement, and project success. For decades, this laborious process depended on manual expertise, long nights over drawings, and the occasional human oversight. But today, a seismic shift is underway.

Artificial Intelligence (AI) is transforming how we approach take-offs. From software that automates measurements to machine learning models that interpret architectural plans with startling precision, the new era of quantity take-offs promises better speed, accuracy, and insight than ever before.

But what does this mean for the modern Quantity Surveyor? And are we heading toward a world where AI replaces human estimators?

So, let’s break it down.

What Are the AI Integrated Take-off Software Out There?

Today, there is an impressive range of quantity take-off software solutions that leverage AI, machine learning, and cloud computing. Here are a few market leaders:

Cubicost

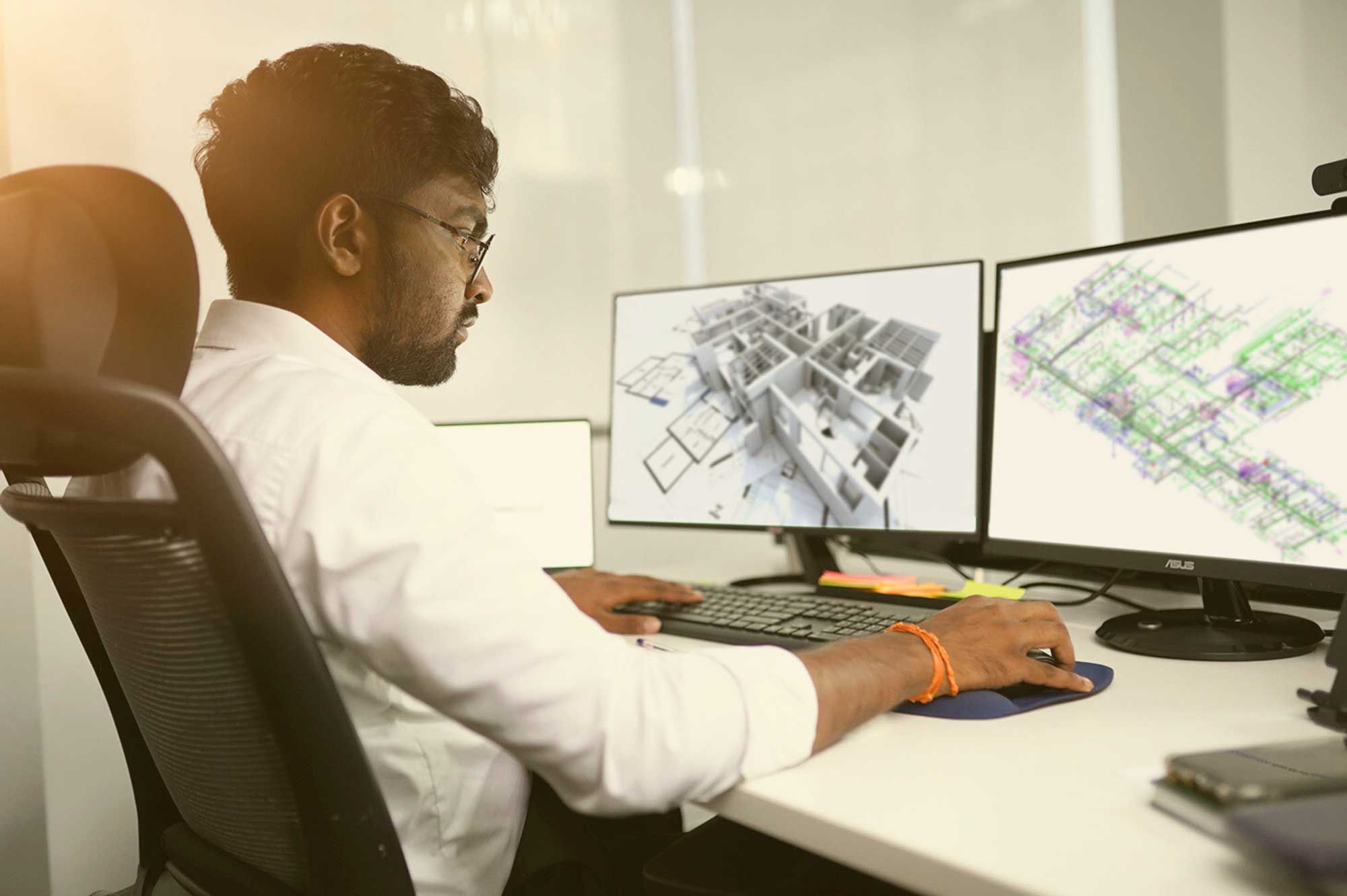

Cubicost is a next-generation quantity take-off and cost estimation suite tailored for BIM-based workflows. It includes four integrated modules (TRB, TAS, TME, TBQ) that extract quantities directly from 3D models or 2D PDFs.

-

Supports IFC, RVT, and DWG files.

-

Automates quantity extraction from structural, architectural, and MEP drawings.

-

Offers 5D simulation for time-cost integration.

-

Widely used by cost consultants for its visualisation, speed, and accuracy in BoQ preparation.

Togal.AI

Togal.AI leverages machine learning and natural language processing to process 2D architectural drawings and rapidly identify areas, components, and measurements.

On-Screen Take-off (OST)

While not fully AI-powered, OST is often used in tandem with automation tools. It allows users to overlay drawing sets, take measurements, and manage markups with precision.

How Can AI Help a Quantity Surveyor in Construction?

AI is not here to replace the Quantity Surveyor, it’s here to supercharge them. Here’s how:

-

Faster Turnaround: What used to take hours can now be done in under an hour. AI speeds up the material quantity take-offs process drastically.

-

Increased Accuracy: AI systems have reached up to 98% accuracy in pilot studies. They reduce the chances of missed items or duplicated counts.

-

Scalable Workflows: Estimators can now handle multiple tenders simultaneously without sacrificing detail.

-

Data-Driven Insights: With every project, AI learns. Over time, it offers benchmarking, cost forecasting, and even risk flags based on past project data.

-

Visual Recognition: AI can scan and interpret architectural drawings, identify layers, and suggest categories.

In essence, AI augments the estimator’s role, allowing them to focus on strategy, value engineering, and commercial advice, not just take-off sheets.

How Are Take-offs Calculated Now?

Traditionally, quantity take-offs required estimators to manually review 2D blueprints or CAD drawings and measure each item using scales, rulers, and digital software. This was often time-consuming and error prone.

With these tools, the process became semi-automated, allowing quantity surveyors to extract dimensions and volumes faster. BIM tools further enhanced this, enabling automatic extraction of quantities from 3D models.

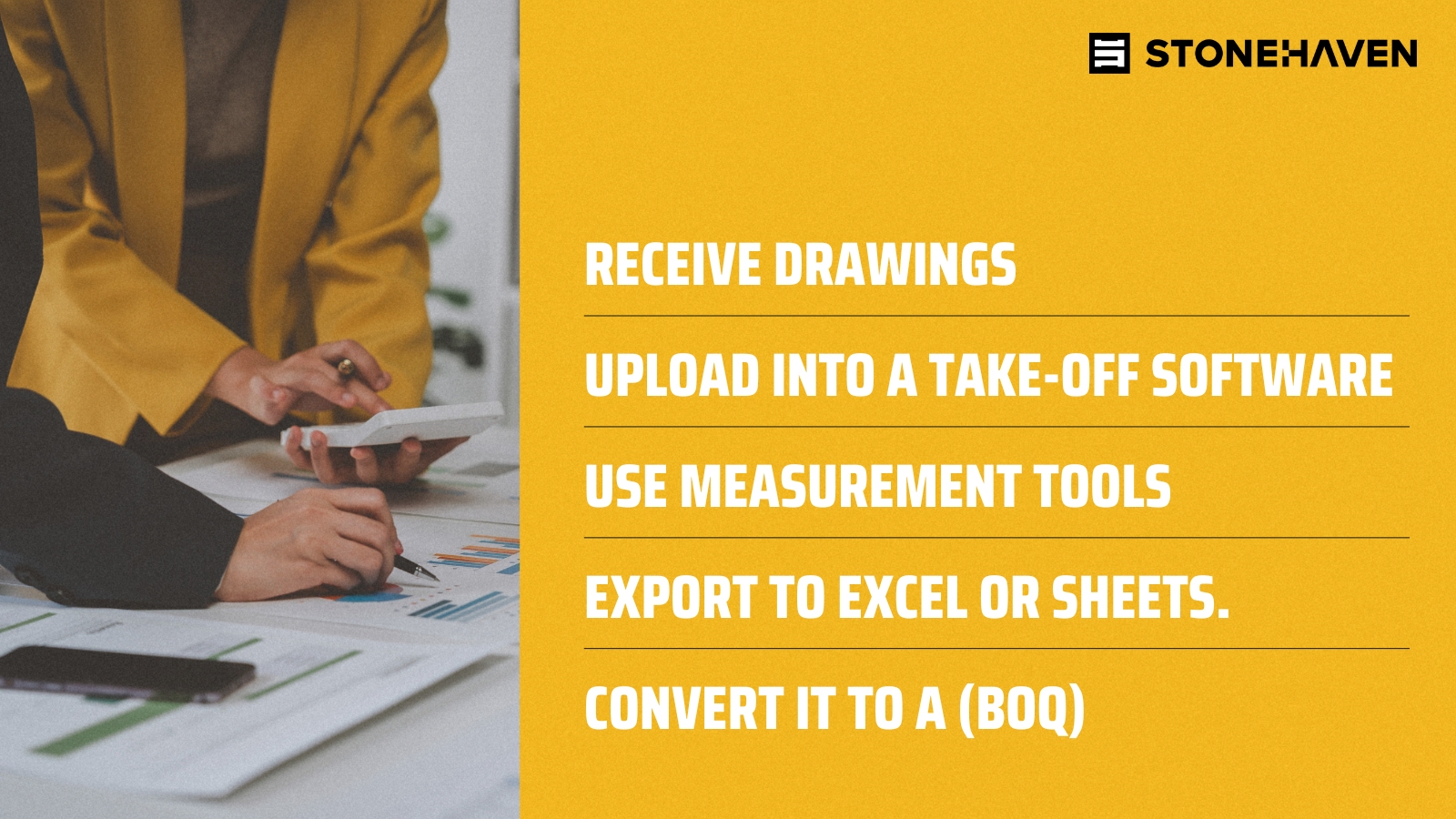

The workflow often looks like this:

Today, with AI-driven platforms, even this can be automated. Upload a plan, and the software can classify elements, quantify, and suggest cost estimates.

Can AI Eventually Take Overestimating and Quantity Take-off Programs?

In some areas, it already has. But complete automation of estimating remains elusive.

AI tools are becoming more adept at performing structured quantity take-offs. However, cost planning still requires contextual judgement, design interpretation, and human input.

What AI can do:

- Convert drawings to quantity take-off sheets automatically.

- Compare previous projects to current ones and suggest adjustments.

- Use a quantity take-off formula to estimate materials with high accuracy.

- Generate detailed quantity take-offs.

What AI can’t do (yet):

- Fully interpret incomplete or ambiguous drawings.

- Apply cost strategies like value engineering.

- Provide nuanced advice during negotiations or risk reviews.

So, while AI is becoming the best software for quantity takeoff in terms of speed, its strategic role is still evolving.

Why Hasn’t BIM Eliminated Manual Estimating Yet?

BIM promised automated quantity take-offs a decade ago. So why are we still measuring from 2D?

-

Inconsistent Model Standards: Designers use different BIM platforms and naming conventions, making it hard for estimators to extract uniform data.

-

Incomplete Models: Many BIM models aren’t detailed enough for estimating. They might lack wall finishes or MEP details.

-

Resistance to Change: Contractors often prefer tried-and-tested methods. Switching to a BIM-only workflow can feel risky.

-

Cost and Training: BIM requires upfront investment in tools and training. Not every firm is ready.

Until model consistency improves and industry-wide standards are enforced, quantity take-offs construction teams will continue using hybrids of manual and digital workflows.

Will AI Be 100% Accurate When Calculating Take-offs?

The short answer: no. But it is getting quite close.

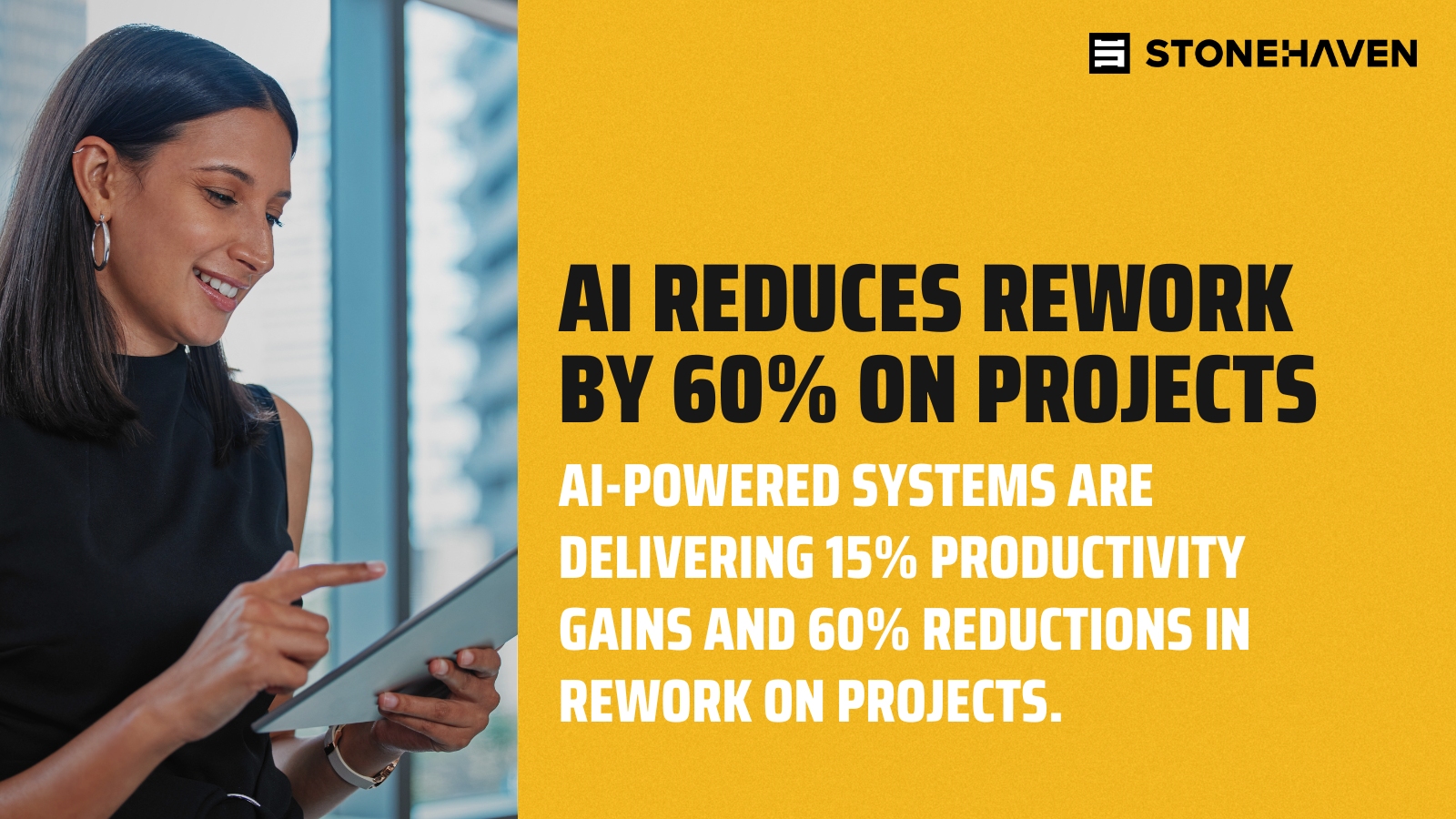

AI-powered systems are delivering 15% productivity gains and 60% reductions in rework. With consistent input data and learning models, accuracy increases over time. But real-world projects introduce variables:

- Design errors

- Model mismatches

- Human oversight during setup

This is why a human Quantity Surveyor still needs to oversee AI-calculated quantity take-offs. Think of AI as your tireless assistant. It doesn’t sleep, but it still needs supervision.

Conclusion

Quantity take-offs have always been foundational to cost planning. With AI and advanced take-off software now in play, the field is evolving rapidly. Estimators are no longer confined to rulers and spreadsheets; they now work alongside AI systems that can measure, calculate, and even predict.

Whether you're looking for a quantity take-off tutorial or exploring the difference between quantity take-off vs bill of quantities, one thing is clear: the future of estimating lies in collaboration between human expertise and machine intelligence.

The firms that adapt to this shift will see better accuracy, faster delivery, and smarter project outcomes.

Featured Perspective

This article includes contributions and insights from Viraj Warunashanka, Cost Manager at Stonehaven whose project experience in the industry has shaped much of this discussion.

Viraj is a Quantity Surveyor with three years of experience in the construction industry. He has worked on a variety of projects, specialising in cost estimation, contract administration, and construction management. With a strong analytical approach and attention to detail, he is committed to delivering cost-effective solutions and maximising value in construction projects.

About us

Stonehaven is a leader in cost management, quantity surveying, and construction consultancy across the Middle East. Our team integrates cutting-edge AI tools with experience to deliver precise, timely, and insightful quantity take-offs for projects across the GCC and beyond.

From material quantity take-offs and BIM integration to full project estimation, our services are designed to help you build smarter. Whether you're searching for the best software for quantity take-off, a tailored quantity take-off tutorial, or guidance on how to do quantity take-offs, we’re here to help.

Let’s build better together.