In an industry where carbon emissions account for nearly 40% of global output, the construction sector has become a critical battleground in the fight for sustainability. The materials we choose aren’t just structural choices, they are environmental declarations. As governments tighten environmental regulations and clients demand greener solutions, the shift toward low-carbon materials in construction is no longer optional; it's inevitable.

But what does "low-carbon" really mean in a construction context? And how can contractors, developers, and general consultants integrate it into every beam, brick, and board? This article unpacks the landscape of sustainable building materials, offering insight into what's new, what works, and what needs to be retired. Drawing from global standards, Sustainable Development Goals (SDGs), and ESG reporting frameworks, we explore how low-carbon materials can reduce environmental impact while still meeting budget and performance requirements.

Whether you're a general contractor navigating construction contracts or a project manager looking to align your build with sustainable development goals, understanding the latest in low-carbon construction materials is key to building smart, and building responsibly.

What Materials Reduce Carbon Footprint?

Reducing carbon emissions in construction begins with rethinking the materials that form the skeleton of our built environment. Conventional choices like concrete, virgin steel, and fired clay bricks are deeply carbon-intensive, with substantial emissions generated during extraction, manufacturing, and transport. In contrast, low-carbon construction materials aim to minimise greenhouse gas emissions across the entire lifecycle, from raw material sourcing to installation and maintenance.

Some of the most effective materials used to lower a project’s carbon footprint include:

Cross-laminated timber (CLT): Engineered by gluing together layers of timber, CLT provides excellent structural performance while sequestering carbon dioxide during the tree’s growth. When responsibly sourced, CLT supports reforestation and offers a renewable alternative to steel and concrete.

Recycled steel: Producing steel from scrap instead of raw ore can cut emissions by as much as 75%, according to a 2025 report by the Global Recycling Foundation. With global recycled steel usage surpassing 460 million tonnes in 2024, it’s becoming an increasingly accessible and sustainable material for load-bearing structures.

Hempcrete: A bio-composite made from hemp fibres and lime, hempcrete is lightweight, non-toxic, and naturally carbon-absorbing. It also provides exceptional insulation properties, making it ideal for passive construction systems. While CLT and hempcrete offer compelling benefits, they remain subject to local code approvals and project-specific constraints. Always assess viability through a full lifecycle cost analysis and compliance review.

Low-carbon concrete alternatives: In construction, low-carbon typically refers to materials and processes with significantly reduced embodied carbon, the emissions associated with material extraction, production, transport, and installation as opposed to operational carbon from energy use post-occupancy.

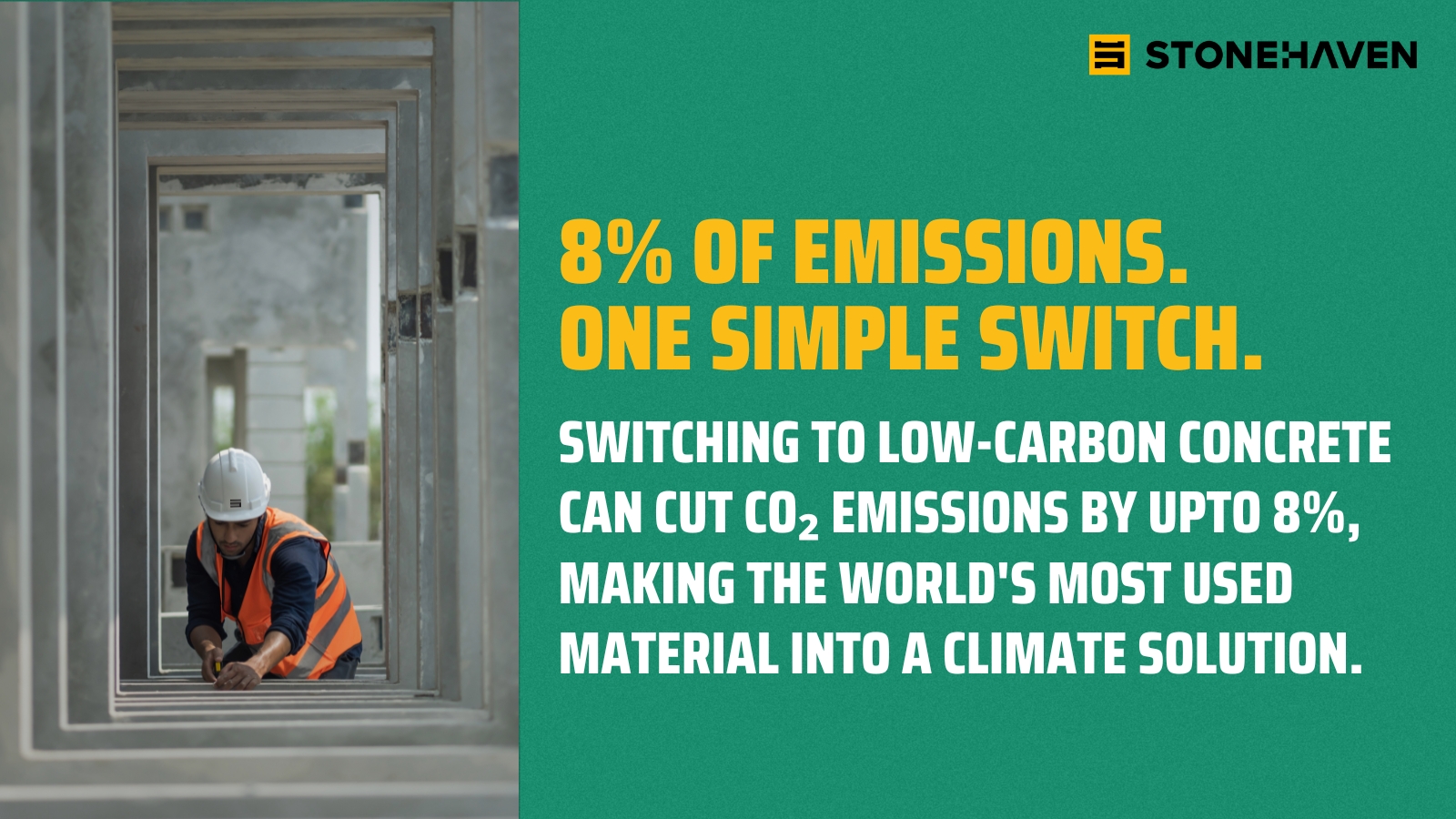

Traditional cement is responsible for about 8% of global CO₂ emissions, but newer formulations incorporating fly ash, ground granulated blast-furnace slag (GGBS), or geopolymers are slashing that figure. According to a 2024 study, substituting 50% of Portland cement with GGBS can reduce embodied carbon in concrete by over 30% without compromising strength.

Low-carbon bricks: Made using compressed earth, recycled aggregates, or fly ash, these bricks reduce energy use in production and support circular construction models. Their thermal mass properties also contribute to long-term energy efficiency in buildings.

These materials don’t just mitigate emissions, they improve energy efficiency, air quality, and even occupant wellbeing. For general contractors, developers, and clients seeking to meet ESG and SDG commitments, incorporating low-carbon materials into construction contracts is no longer an optional add-on. It’s essential groundwork for a net-zero future.

What Are the New Low Carbon Materials?

One of the most promising innovations is Mycelium insulation. Derived from the root network of fungi, mycelium can be grown in moulds to create lightweight, fire-resistant, and biodegradable panels. Unlike synthetic insulation materials, mycelium products require minimal energy input and are compostable at end-of-life, making them ideal for circular construction models.

Then there’s Ferrock, a revolutionary alternative to traditional cement. Made from recycled steel dust and silica, Ferrock hardens through exposure to carbon dioxide, actively absorbing CO₂ during the curing process. This makes it a carbon-negative material, offering both high compressive strength and a net positive climate impact.

Algae-based building panels are another bold frontier. These “living” facades contain microalgae that photosynthesise, producing oxygen and capturing carbon in real time. While still in early phases of commercialisation, prototypes have shown promise in regulating indoor temperatures and generating renewable biomass for biofuels.

Equally compelling are recycled plastic bricks, which offer a dual sustainability benefit: repurposing plastic waste and reducing the energy footprint associated with traditional clay bricks. Interlocking designs eliminate the need for mortar, enabling faster, cleaner construction methods, particularly valuable in temporary or low-income housing developments.

Finally, CarbonCure Concrete has emerged as a game-changer in mainstream construction. By injecting captured CO₂ into concrete during mixing, the technology not only locks away harmful emissions permanently but also enhances the compressive strength of the final product. This innovation has already been deployed in commercial and residential projects across North America and the Middle East, with a growing footprint in UAE construction tenders that prioritise ESG performance.

These materials are more than novelties. For contractors and developers, early adoption of low-carbon alternatives can strengthen bids, meet tightening regulatory standards, and deliver lasting environmental impact. As climate policies become more binding, those who integrate these solutions early will be leading the charge, not catching up.

While these materials show immense promise, several remain in pilot or early commercialisation stages. Their feasibility depends on project scale, local market readiness, and investor appetite for innovation.

What Are the More Unsustainable Construction Materials?

Before we build better, we must understand what we must leave behind. The path to sustainable construction doesn’t begin with innovation, it begins with phasing out the materials that have silently contributed to the climate crisis for decades. Unsustainable construction materials are not just outdated, they’re environmentally costly. They contribute heavily to greenhouse gas emissions, exhausting finite natural resources, and often carry toxic by-products that affect both ecological and human health.

1. Portland Cement: Cement is one of the most widely used substances on Earth, and also one of the most carbon-intensive. For every tonne of ordinary Portland cement produced, approximately 0.9 tonnes of CO₂ are released. This staggering figure contributes to cement being responsible for around 8% of global CO₂ emissions. Despite its structural importance, its environmental cost makes it a prime target for replacement with alternatives like GGBS, fly ash, or calcined clay.

2. Virgin Steel: Steel production without recycling relies heavily on coking coal and energy-intensive blast furnaces. This process generates large amounts of carbon dioxide, sulphur oxides, and other harmful emissions. Without using recycled content, steel remains one of the construction industry’s most polluting inputs.

3. PVC (Polyvinyl Chloride): Widely used for pipes, window frames, and flooring, PVC is derived from petroleum and contains additives like phthalates, heavy metals, and dioxins, many of which are toxic or carcinogenic. It’s resistant to degradation, meaning it persists in landfills and oceans, leaching microplastics into ecosystems.

4. Aluminium (non-recycled): While aluminium is prized for its light weight and corrosion resistance, producing it from raw bauxite consumes massive energy. Virgin aluminium has one of the highest embodied carbon footprints of any construction material, particularly when smelted using fossil fuel-based electricity.

5. Traditional Fired Clay Bricks: The production of fired bricks typically involves burning coal or natural gas at high temperatures in kilns, releasing large volumes of carbon dioxide, sulphur dioxide, and particulate matter. This process not only emits pollutants but often depletes topsoil and impacts air quality in surrounding communities.

Thankfully, the tide is turning. From the EU Green Deal to the UAE’s National Climate Change Plan, legislation is increasingly encouraging the use of sustainable alternatives. Environmental Product Declarations (EPDs) and certifications like BREEAM, LEED, and Estidama are helping the industry pivot toward transparency and accountability.

For contractors, developers, and specifiers, understanding the impact of these legacy materials isn’t just a regulatory box to tick, it’s a necessary step in future-proofing projects and meeting climate resilience goals.

What Is an Example of Low-Carbon Infrastructure?

Low-carbon infrastructure goes beyond swapping out materials, it's about reimagining the way we build, operate, and decommission our built environment. These developments aim to reduce emissions across every phase of the construction lifecycle: design, material sourcing, construction methodology, energy performance, and end-of-life recovery. The result is infrastructure that doesn’t just function efficiently, but actively contributes to broader sustainability goals, ESG benchmarks, and national climate commitments.

One prominent example is the Jetex Al Bateen VIP Airport Lounge in Abu Dhabi, delivered ahead of COP28. Achieving an Estidama 3 Pearl rating, the project incorporated sustainable materials, efficient HVAC systems, and an optimised lighting design, prioritising both occupant comfort and operational carbon reduction. Projects like these demonstrate that low-carbon design can be seamlessly integrated into luxury, high-performance environments without compromising on aesthetics or functionality.

Another flagship project is the Miss Tess Restaurant & Lounge in Dubai, completed in 2022. Stonehaven provided post‑contract project and cost management for this approximately 1,200 m² hospitality venue within the Taj Hotel Downtown Dubai. Design highlights included timber tones, vintage red finishes, and bamboo features.

The impact of these approaches is multifaceted:

- Lower lifetime operating costs, due to reduced energy consumption

- Improved ESG scores and investor appeal, particularly for real estate portfolios

- Enhanced user experience and wellbeing, thanks to better air quality, thermal comfort, and daylight use

- Reduced exposure to regulatory risk, as green building codes tighten worldwide

From solar-ready rooftops and modular systems to recycled aggregates and water reuse networks, low-carbon infrastructure isn’t futuristic, it’s already here. The question for developers and general contractors is no longer “if” but “how fast” they can scale it. And for those who do, the rewards are both environmental and economic.

Is Low-Carbon Concrete Sustainable?

Concrete is the most widely used construction material on Earth, and one of the most environmentally damaging. Responsible for up to 8% of global CO₂ emissions, Portland cement is a significant contributor to embodied carbon in buildings and infrastructure. However, low-carbon concrete solutions are offering a transformative shift for the industry.

Sustainable concrete alternatives centre on reducing or entirely replacing Portland cement with less carbon-intensive materials, while maintaining structural strength and durability. One major pathway is the use of Supplementary Cementitious Materials (SCMs), industrial by-products such as fly ash, ground granulated blast-furnace slag (GGBS), and silica fume. These can reduce embodied carbon by up to 40% depending on mix ratios, while also enhancing durability.

Geopolymer concrete, based on alkali-activated binders, offers yet another promising alternative. These materials use aluminosilicates (often derived from industrial waste) and produce significantly lower emissions compared to traditional Portland cement.

Optimising mix designs and using lightweight structural systems or prefabricated components can also reduce the total volume of concrete required, slashing overall carbon impact without compromising structural integrity.

Though once considered niche, these alternatives are rapidly gaining ground. In the UAE and Saudi Arabia, where national visions include bold carbon neutrality targets, green concrete is now actively encouraged through policy and procurement frameworks. Public-private pilot projects and infrastructure upgrades are increasingly calling for SCM-based or carbon-capture concrete options as standard.

The takeaway is clear: low-carbon concrete is not only feasible, but also becoming foundational to the future of sustainable construction.

Conclusion

Low-carbon construction isn’t a futuristic concept; it’s today’s competitive edge. As ESG reporting becomes standard, and climate-conscious clients drive procurement choices, the construction sector must evolve. From low-carbon bricks to recycled concrete, new materials are redefining what it means to build responsibly.

Embracing low-carbon building materials not only aligns with global sustainability goals, such as the UN SDGs, but also future-proofs projects against regulatory, financial, and reputational risks. For general contractors, consultants, and developers, integrating these materials isn’t just good PR, it’s a smart strategy.

About Us

At Stonehaven, we help you build better, cleaner, smarter, and more sustainably. As one of the UAE’s leading consultancies for construction sustainability, we specialise in embedding low-carbon strategies into every stage of your project’s lifecycle, from pre-construction planning to post-occupancy performance.

Our interdisciplinary team brings together sustainability consultants, certified green building experts, project managers, and cost engineers who collaborate to reduce your project's environmental footprint while maintaining technical excellence and financial control. Whether you’re working on a commercial tower, airport lounge, hospitality space, or infrastructure upgrade, we tailor our services to meet both regulatory expectations and future-focused ESG standards.

We offer full-spectrum support in sustainable materials sourcing, low-carbon concrete specification review, and integration of green building frameworks such as LEED, Estidama, and the UAE’s Net Zero 2050 Strategy. Our consultants also support ESG and SDG-aligned reporting, ensuring that your build doesn't just meet compliance benchmarks but actively contributes to global development goals. Through carbon accounting and lifecycle assessments (LCA), we help you measure impact, mitigate emissions, and plan for a more resilient future.

If you're ready to future-proof your next project with low-carbon materials, smarter systems, and transparent sustainability reporting, we’re here to help you lead that change.