Construction is the backbone of modern infrastructure, driving urban development, housing, transport systems, and industrial growth. Yet, beneath every towering skyscraper or efficient drainage system lies a core set of documents that guide its realisation: construction drawings. Among these, IFC drawings, short for "Issued for Construction,” are among the most critical.

In 2025, with construction workflows turning increasingly digital and global projects growing in complexity, the need for clear, finalised construction documentation is more important than ever. IFC drawings are the legal, operational, and coordination foundation of a project.

In this article, we demystify what IFC drawings are, how they work, and why your cost manager can’t afford to overlook them.

What Are IFC Drawings in Construction?

In the world of construction, clarity is everything. From complex infrastructure projects to high-end residential towers, teams rely on precise, coordinated documentation to transform ideas into physical structures. One of the most crucial sets of documents in this process is the IFC drawing package. IFC stands for Issued for Construction, and these drawings represent the final, approved version of the design, ready for execution on-site.

IFC drawings are not early-stage sketches or rough drafts. They are the authoritative, stamped documents that have undergone comprehensive design coordination, stakeholder reviews, and regulatory approvals. By the time they reach a construction site, every component, be it a foundation layout or a duct routing plan, has been reviewed by architects, engineers, project managers, and often government authorities.

These drawings encompass all the major disciplines required for construction: architectural plans, structural frameworks, mechanical, electrical, and plumbing (MEP) systems, civil works, and sometimes even specialised packages like landscaping, interiors, and sustainability systems. Unlike schematic or design development drawings, IFC documents are legally binding and form an integral part of the construction contract. They carry not only technical details but also legal weight, holding parties accountable to specifications, materials, and performance standards.

The value of IFC drawings lies in their role as the single source of truth. For contractors and subcontractors, they are the primary guide for building; for cost consultants and quantity surveyors, they’re the basis for procurement and variation control; and for clients, they represent what has been promised and approved.

Recent industry data shows why this matters: a staggering 71% of contractors cite material shortages and lead-time delays as the primary cause of project holdups. Without clear and timely IFC drawings, procurement suffers and delivery timelines spiral. Similarly, 68% of trade professionals point to poor schedule management, often rooted in incomplete or revised documentation, as the leading cause of productivity drops. In short, well-prepared IFC drawings aren’t just helpful, they’re mission-critical.

They bridge the gap between design intent and physical reality, ensuring that what has been envisioned on paper is what gets built, on time, on budget, and to standard.

What Is the Main Purpose of IFC Drawings?

The construction site is a complex ecosystem. Multiple teams operate in tandem, each with distinct roles, timelines, and deliverables. Without a unified set of documents to anchor the build, confusion can spread rapidly, decisions become reactive, and mistakes escalate. That’s why IFC drawings are so critical. They’re not just about showing what needs to be built; they’re about how, when, and with what level of precision and compliance.

At their core, IFC drawings are designed to align all stakeholders, from architects to subcontractors, on the approved, final vision of the project. They remove ambiguity, formalise accountability, and streamline the path from design to delivery.

1. Clarity and Coordination

Modern construction relies on multi-disciplinary collaboration. Architectural layouts must interface seamlessly with structural grids, MEP systems, and civil works. IFC drawings ensure that every team is referring to the same version of the design, updated with the latest revisions and free of discrepancies. By providing a single source of coordinated truth, these documents reduce the risk of onsite clashes, misinterpretations, or costly duplication of work.

2. Legal Reference

IFC drawings carry legal weight. Once issued, they become binding components of the construction contract. They specify what the contractor is being paid to deliver and offer a basis for assessing performance, compliance, and disputes. If disagreements arise around quality, scope, or variation, IFC documentation becomes the benchmark against which claims are evaluated. In this sense, they safeguard both client and contractor interests.

3. Project Efficiency

Delays in decision-making, unclear instructions, or late-stage design changes can bring projects to a standstill. IFC drawings help preempt these bottlenecks by locking design decisions before construction begins. With clear, coordinated plans, procurement can be faster, sequencing more logical, and site logistics easier to manage. IFC drawings help teams move confidently, without constant back-and-forth for clarification.

4. Risk Mitigation

Construction carries inherent risk, structural, financial, and reputational. Poorly documented projects face higher chances of error and rework. IFC drawings serve as a defence against these risks by offering a detailed, vetted framework for execution. When followed correctly, they support safer builds, better resource planning, and higher-quality outcomes.

Who Issues the IFC Drawings?

IFC drawings represent the final iteration of a project’s design documentation, and their issuance marks a critical milestone in the construction lifecycle. These drawings are typically issued by the project’s design consultants, but this doesn’t mean a single entity produces them in isolation. Rather, they are the outcome of a multi-layered, collaborative process that requires careful coordination across disciplines and stakeholders.

The responsibility for issuing IFC drawings rests primarily with the lead consultant or design architect, who oversees the integration of inputs from various design teams. These teams include:

● Architects, who develop and refine the overall design intent, everything from spatial planning and façade treatments to interior finishes and material specifications.

● Structural engineers, who ensure the integrity of the load-bearing systems and provide detailed drawings for foundations, columns, beams, and reinforcement.

● MEP (Mechanical, Electrical, and Plumbing) engineers, who contribute detailed schematics for HVAC systems, lighting, power distribution, water supply, drainage, fire protection, and more.

● Civil engineers, who address site-related aspects such as grading, road layouts, utilities, and stormwater drainage.

● Project managers, who oversee the timeline, ensure that documentation complies with regulatory standards, and maintain alignment with the client’s goals.

● Clients and relevant authorities, who review the completed design package for compliance with statutory regulations, contract deliverables, and technical expectations.

Only once all these parties have completed their reviews and approvals can the drawings be formally stamped and issued for construction. The final IFC set becomes a contractual document, distributed to all relevant stakeholders, including the main contractor, subcontractors, quantity surveyors, and procurement teams.

In today’s digital construction environment, IFC drawings are usually compiled and issued as part of a cloud-based documentation platform. If the project uses Building Information Modelling (BIM), the term “IFC” may also refer to Industry Foundation Classes, an open, non-proprietary file format used to enable interoperability between different BIM software platforms. While these are distinct from Issued for Construction drawings, they often work in tandem: the 3D BIM model (exported in IFC format) complements the 2D IFC drawing set, allowing for better visualisation, coordination, and clash detection before construction begins.

Issuing IFC drawings is, therefore, not a single action but a carefully understood process of sign-offs, integrations, and formal approvals, ensuring that the project is ready to move from design to physical execution with confidence and compliance.

What Is the Process of Issued for Construction (IFC) Drawings?

The journey from a conceptual design to a fully executable set of construction drawings is meticulous and collaborative. Here’s a breakdown of how IFC drawings are typically developed and formalised:

1. Design Finalisation

The process begins once the overall design concept has been approved. The consultant team, including architects, engineers, and other specialists, works collaboratively to develop the full suite of construction documentation. These drawings detail every aspect of the build: architectural layouts, structural systems, mechanical ventilation routes, electrical wiring diagrams, plumbing schematics, civil works, and any specialised packages like façade systems, sustainability features, or landscape elements.

At this stage, the aim is to eliminate ambiguity. Every material, dimension, and specification is documented, ensuring the design is technically feasible and ready for construction.

2. Review and Coordination

Once each discipline has completed its portion of the drawings, a comprehensive coordination review takes place. This is where cross-disciplinary alignment is critical. Using manual checks or digital Building Information Modelling (BIM) tools, the design team verifies that systems do not clash, e.g., a structural beam doesn’t obstruct an air duct or cable tray. Regulatory requirements, local building codes, fire safety standards, and client-specific benchmarks are also carefully reviewed at this stage.

This process reduces the risk of rework during construction, ensuring that the design package is buildable and compliant.

3. Revisions and Quality Assurance

After coordination, the drawings are returned to relevant consultants or engineers for final revisions. These updates may reflect technical feedback, regulatory clarifications, or cost-saving strategies. Specifications are double-checked for consistency, and all drawing references are confirmed.

Quality assurance teams often perform a final audit, ensuring no critical detail has been overlooked, and the documentation meets professional and legal standards.

4. Approval and Release

Once the revised set has been approved by all stakeholders, the documents are stamped, marked as “Issued for Construction,” and logged into the project’s document control system. This moment signifies the formal transition from design to execution.

5. Distribution and Archiving

The final IFC drawing set is distributed to all key construction stakeholders; main contractors, subcontractors, procurement managers, and site engineers. Most teams today use centralised cloud-based platforms (like Procore or Autodesk Construction Cloud) to ensure real-time access and version control.

IFC drawings are also archived to preserve the record of design intent, which may be referenced for future renovations, legal claims, or facility management.

Why Are Accurate IFC Drawings Important for Quantity Surveyors?

For Quantity Surveyors (QSs), accurate Issued for Construction (IFC) drawings are not just technical documents, they are the foundation of cost certainty, procurement strategy, and contract control. When these drawings are incomplete, misaligned, or issued with unresolved coordination issues, the QS function becomes reactive, speculative, and vulnerable to claims.

1. Accurate BOQs Depend on Accurate IFCs

The preparation of a reliable Bill of Quantities (BOQ) begins with a clear understanding of scope, dimensions, and material specifications. IFC drawings provide the QS with this quantifiable data. Any ambiguity from missing details, conflicting notes, or undefined extents can result in incorrect quantities, skewed pricing, and commercial risk.

2. Variation Management Starts with IFC Clarity

IFC drawings serve as the contractual baseline. When site conditions or client instructions deviate from this benchmark, variations are assessed. If the IFC set is vague or contradictory, it becomes difficult for the QS to assess entitlement, quantify the impact, and prepare robust variation submissions or evaluations.

3. Procurement and Tendering Decisions Rely on Scope Certainty

When IFCs are well-coordinated, the QS can break down trade packages with precision. This clarity enables competitive tendering, apples-to-apples comparison of contractor pricing, and early identification of provisional sums or exclusions. In contrast, unclear drawings lead to contractor assumptions, many of which become costly change orders post-award.

4. Cost Risk Is Contained at the Source

Projects that begin with accurate IFC drawings benefit from stronger cost control. Risks associated with design gaps, double counting, or missed elements are reduced. This enables the QS to offer clients better forecasts, tighter budgets, and fewer post-contract disputes.

In short, accurate IFC drawings allow Cost managers to shift to governance. They enable proactive cost management rather than reactive claims defence, making them essential for every commercial success story on site.

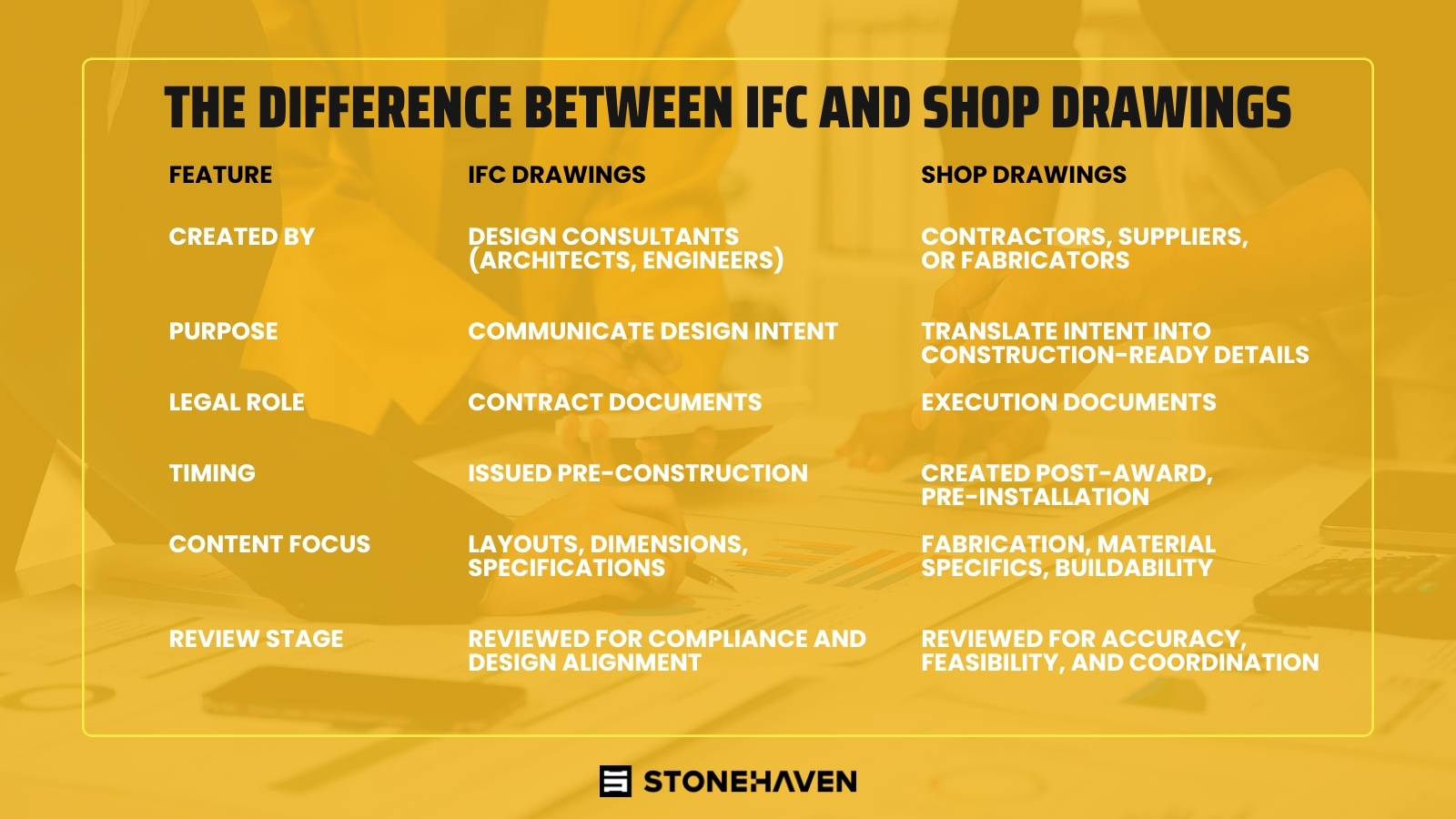

What Is the Difference Between IFC and Shop Drawings?

In the lifecycle of a construction project, both IFC (Issued for Construction) and shop drawings play essential roles, but they are fundamentally different in purpose, origin, and level of detail. While they may appear similar to the untrained eye, understanding the distinction between the two is critical for proper project planning, procurement, and on-site coordination.

IFC drawings are created by the project’s design consultants, usually architects and engineers, and represent the approved design intent of the project. These documents are issued during the pre-construction phase and serve as the formal blueprint for what the building should become. Importantly, IFC drawings are part of the legal contract documentation, binding both the client and contractor to a specific scope of work.

Shop drawings, on the other hand, are developed after the issuance of IFC drawings, typically by the contractors, subcontractors, suppliers, or fabricators. They are far more detailed and specific, focusing on how components will be manufactured, assembled, and installed. These drawings often reflect real-world constraints, such as supplier specs, construction techniques, or material substitutions, and include precise fabrication details, installation sequences, and tolerances.

In essence, shop drawings are an extension of IFC drawings. They provide the missing layer of specificity needed to move from concept to physical construction, enabling site teams to procure materials, fabricate components, and install systems with confidence and precision.

Conclusion

In a construction environment where time, money, and quality are constantly at stake, IFC drawings serve as the backbone of effective project delivery. These drawings consolidate design decisions, ensure regulatory compliance, and form a legal basis for execution. Without a well-coordinated IFC drawing package, construction sites are vulnerable to miscommunication, delays, and budget overruns.

As the industry embraces digitalisation and collaborative platforms, the importance of clear, consistent, and compliant IFC drawings will only grow. Whether you're a project manager, developer, or contractor, understanding how IFC drawings function is essential to successful delivery in 2025 and beyond.

Featured Perspective

This article includes contributions and insights from Jayani Bandara, Cost Manager at Stonehaven whose project experience in the industry has shaped much of this discussion.

Jayani is a Quantity Surveyor with two years of professional experience in the construction industry having worked across local and international projects in the UAE, Saudi Arabia, UK, and Australia. She holds a bachelor’s degree in quantity surveying and has been actively involved in cost estimation, BOQ preparation, and tender documentation, with hands-on expertise in software such as CostX, Cubicost, Bluebeam, and PlanSwift.

About Us

At Stonehaven, we provide expert construction cost management, project controls, and sustainability-driven consultancy for developments across the UAE. We believe that a successful construction project depends not just on great design, but on detailed, forward-thinking financial planning and documentation that leaves no room for uncertainty. Our team works closely with clients, architects, and contractors to ensure budgets, procurement strategies, and timelines are fully aligned with IFC drawings and other key deliverables.

From early-stage cost modelling to guiding transitions between IFC and shop drawings, we support projects with precision and clarity. We also manage contract administration and conduct detailed claims reviews, helping clients navigate the legal and financial aspects tied to issued-for-construction documentation.

Whether you're delivering a rapid-build infrastructure project or a high-spec residential development, our approach combines technical expertise with practical insight to keep your project on track and within scope.