In the ever-evolving landscape of construction project management, one principle remains consistent: no plan survives first contact with reality. From sudden shifts in client expectations to unexpected site conditions, even the most meticulously planned building projects are prone to change. For construction professionals and project owners alike, these changes come at a cost, both literal and logistical. Enter the variation order.

Variation orders, also known as change orders, are essential tools in the arsenal of effective construction management. They are the formal, contractual instruments that allow for modifications to the scope, cost, or timeline of a construction project after work has begun. Without them, projects would grind to a halt at the first sign of deviation from the original plan.

In the UAE and GCC construction sectors, where rapid urbanisation and mega-developments are the norm, variation orders are not only common, they are inevitable. Managing them with precision, transparency, and strategic foresight can be the difference between a profitable venture and a financial drain. This article dives deep into the world of variation orders in construction cost management, shedding light on their role, risks, and rewards.

Whether you're a project manager, cost consultant, developer, or stakeholder, understanding how to navigate variation orders is crucial. It not only ensures smoother operations but also enhances project profitability and strengthens your reputation in a competitive market.

What is a Variation Order in a Construction Project?

A variation order is a formal directive issued during the lifecycle of a construction contract that authorises a change to one or more elements of the originally agreed scope of work. These changes can be as minor as substituting a different brand of tiles, or as substantial as redesigning entire structural components. Variations may affect a wide range of project aspects, including the quantity of work, the materials and methods used, the design specifications, or the quality standards to be maintained. They can also have direct consequences on both the overall project budget and the scheduled completion timeline.

In the day-to-day operations of a construction site, variation orders are far from rare. For example, a developer might decide mid-project to change the type of flooring from ceramic to marble to improve the property’s premium feel. Alternatively, local authorities might introduce updated safety regulations requiring the contractor to switch out mechanical systems or reinforce structural elements. Whether driven by aesthetics, compliance, or functionality, these modifications cannot be implemented informally. They must be captured, reviewed, and approved through a transparent and documented process.

A 2024 study published in Buildings journal found that change orders, including those due to compliance updates and design shifts, can increase project costs by up to 10% and are implicated in over 60% of construction disputes globally. This is particularly relevant in high-growth markets like the UAE, where the total value of construction projects reached an estimated $590 billion in Q1 2024, with mixed-use and residential developments comprising a significant portion. As the project pipeline continues to expand and evolve, the role of variation orders becomes even more central to budget and risk management.

At their core, variation orders serve multiple critical functions:

● They uphold legal and financial clarity, making it possible for both client and contractor to refer back to a shared, updated scope and cost.

● They create an accountability mechanism, ensuring that all changes are traceable and that no work is carried out without client approval.

● They enable agile, responsive project delivery, allowing for design evolution and problem-solving without stalling the broader schedule.

● They reduce the risk of disputes, offering a contractual framework that mitigates the blame game when complications arise.

Almost all standard forms of contract, including the FIDIC Red Book, which is widely used in the UAE and broader GCC, include comprehensive clauses dealing with variation orders. These outline not only when and how variations may be requested, but also how they must be evaluated, costed, approved, and resolved in case of disagreements. Understanding these provisions is essential for contractors, consultants, and project managers alike, as variation orders are one of the most common and potentially contentious areas in construction contract administration.

What are the Most Common Reasons for Variations?

Variations arise from a wide array of causes. Some are due to external, uncontrollable circumstances, while others emerge from internal decisions or planning oversights. Let’s explore the most frequent catalysts:

1. Client-Initiated Changes

Clients often revise their requirements mid-project. This may stem from evolving needs, aesthetic reconsiderations, or new market insights. For instance, a luxury hotel developer might decide mid-way to upgrade finishes to better compete with newer resorts nearby.

2. Design Errors or Omissions

Even with the most rigorous design phase, errors can slip through. Missing structural components, uncoordinated services, or inconsistent measurements can necessitate rework and additional work.

3. Unforeseen Site Conditions

Subsurface conditions such as rock formations, underground utilities, or water tables not identified in preliminary surveys often lead to variations. In regions like Dubai and Abu Dhabi, where construction sites may be reclaimed land or near coastlines, this is a frequent issue.

4. Regulatory or Code Updates

Changes in local regulations, be it fire safety, green building compliance, or health standards, can require midstream alterations. For instance, Abu Dhabi’s Estidama Pearl Rating system or Dubai’s Green Building Code can result in necessary design modifications.

5. Material or Equipment Unavailability

Construction in the GCC often relies on imported materials. Supply chain disruptions, price escalations, or embargoes can make initially selected materials unattainable, leading to substitutions.

6. Contractual Misinterpretations

Ambiguities in contract language or misunderstanding of scope can lead to disputes and, eventually, variation orders to align expectations and realities.

Understanding these causes allows teams to plan proactively, include buffer allowances, and maintain a healthy contingency strategy.

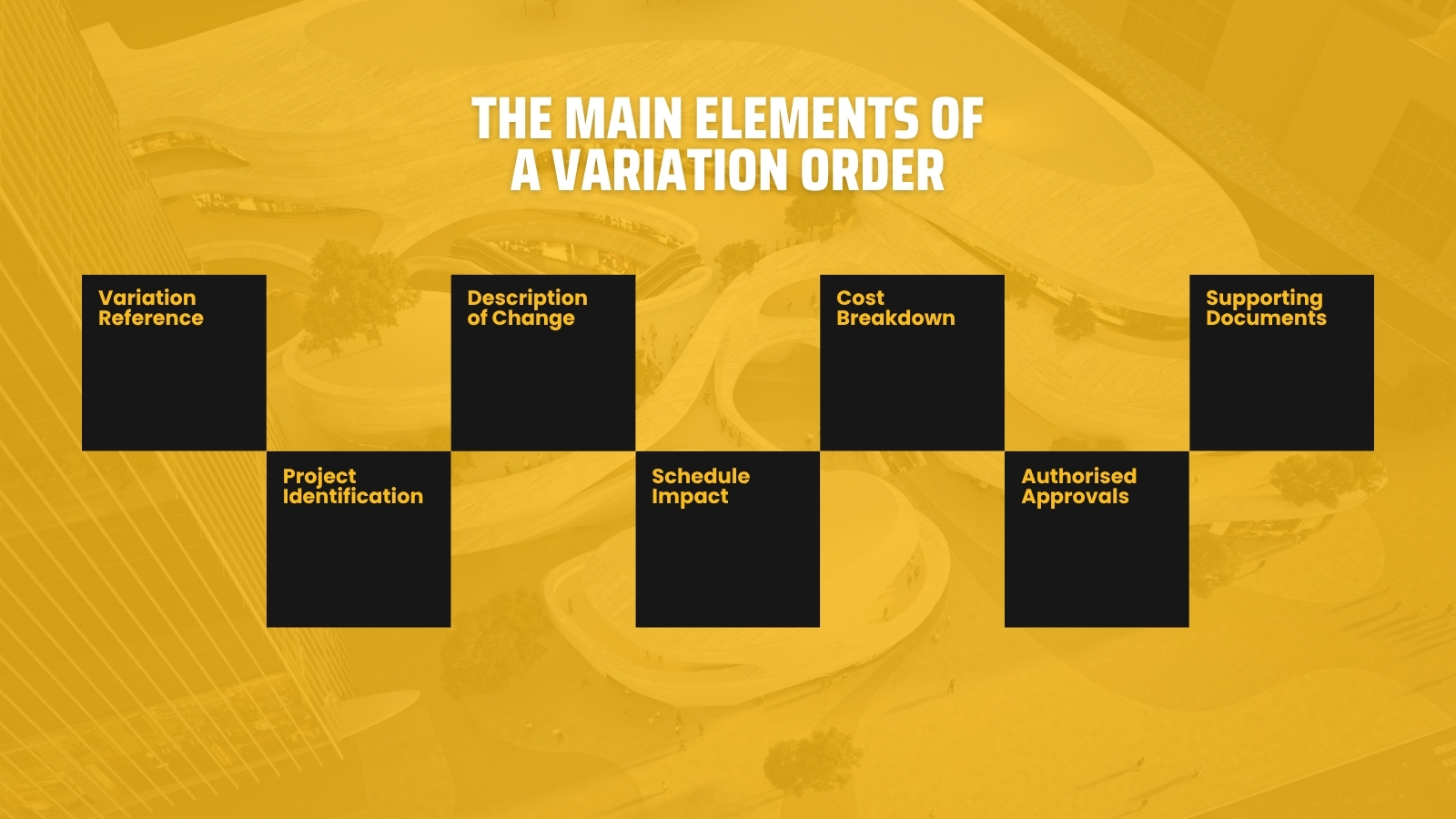

What are the Main Elements of a Variation Order?

Every variation order must be treated as a formal legal document, not a casual discussion or side agreement. In fast-paced construction environments, particularly within the UAE and GCC markets, relying on informal instructions can lead to disputes, cost overruns, and significant legal exposure. A variation order, when structured correctly, becomes a vital record of mutual agreement between parties and a roadmap for implementing the approved changes with minimal disruption.

Let’s examine each essential component in greater detail:

1. Variation Reference Number

Every variation should have a unique identifier that links it to the broader contract documentation, logs, and financial reports. This reference number allows for clear tracking, auditing, and historical analysis across the project's lifespan. Without it, variations can be lost in communication or misattributed in accounting systems.

2. Project Identification

This includes the project name, location, principal contractor, contract package, and original contract number. In large developments, such as those in Dubai’s real estate sector, multiple variations may occur across different building zones or phases. Clear identification ensures variations are applied to the correct portion of the works.

3. Description of Change

This section must be as specific and detailed as possible. What exactly is changing? Why is the change necessary? Who initiated it? Which trades, subcontractors, or disciplines are affected? For example, changing from gypsum partitions to blockwork due to fire-rating requirements must be explained not only in scope but in context.

4. Impact on Schedule

Even small variations can have ripple effects. If additional steelwork is required for an extended canopy, does this affect the delivery schedule of facade systems? Or can the variation be incorporated without any delay by adjusting resource allocations? This section quantifies those impacts with adjusted milestone dates or identifies “no impact” declarations.

5. Cost Breakdown

The cost implications should be broken down clearly into labour, materials, plant, subcontractor charges, preliminaries, and profit margins. Many GCC contractors use cost-loaded programmes or BIM-integrated estimation tools, so including BOQ line-item references or rate justifications improves transparency and auditability.

6. Authorised Approvals

Without authorised sign-off, a variation is merely a suggestion. The variation form must include signatures from all parties stipulated in the contract, typically the client, contractor, and supervising consultant. In larger government-funded projects, approvals might require the oversight of contract administrators or third-party quantity surveyors.

7. Supporting Documents

Drawings, specifications, supplier quotes, design reports, method statements, and compliance certificates should accompany the variation order. These substantiate the necessity and scope of the change and ensure that the parties are operating with the same understanding.

An incomplete variation order, lacking justifications or proper approvals, can stall progress payments, prompt legal claims, and strain professional relationships. Precision in documentation is not just a bureaucratic exercise; it is foundational to the financial and legal health of a construction project.

What are the Types of Variation Orders in Construction?

Variation orders are not a monolith, they vary by their origin, intent, and consequence. Classifying them accurately enables the project team to better manage stakeholder expectations, budgeting strategies, and contractual obligations. Here's a closer look at the key categories of variation orders in construction:

1. Directed Variations

These are the most straightforward. The client or employer formally instructs the contractor to carry out a change, perhaps to meet new branding guidelines, expand a building's footprint, or add premium finishes. Directed variations are common in design-build contracts and typically follow a clear top-down communication protocol.

Example: In a hotel construction project, the client may issue a directed variation to replace standard ceramic tiles with imported marble to match their brand standards globally.

2. Constructive Variations

These are more nuanced. Constructive variations occur when a contractor is forced to deviate from the contract due to inconsistencies, contradictions, or vagueness in the original design documents. Though not explicitly directed, the change becomes inevitable due to gaps in the project’s original planning.

Example: A clash between HVAC ducting and structural beams in the shop drawings might require rerouting systems, a change that wasn't originally specified but becomes necessary to proceed.

3. Beneficial Variations

Also known as value engineering variations, these are usually contractor-initiated and aimed at improving project outcomes, whether in cost, schedule, or sustainability. While they must be approved, they often strengthen contractor-client trust and can improve margins for both.

Example: Proposing to use lightweight concrete blocks instead of traditional ones to reduce structural load and speed up installation.

4. Detrimental Variations

Unfortunately, not all variations yield benefits. Some result from poor planning, late decision-making, or errors. These tend to increase costs and may even compromise quality or safety. They are often the most contentious, and a thorough change impact analysis is required.

Example: Discovering a missing structural element in the approved architectural design that must now be retrofitted mid-construction, leading to time delays and redesign costs.

5. Zero-Cost Variations

These don’t directly affect the contract sum but still alter the design, schedule, or technical requirements. They’re often used to formalise changes that have no immediate monetary impact but could influence downstream works or maintenance.

Example: A client may change the colour of aluminium cladding after procurement but before installation, with no additional cost, yet requiring documentation and client approval.

Understanding these types helps contract administrators frame their documentation properly, price variations accurately, and prepare clients for potential consequences early on.

Factors You Have to Consider in Variations in Projects

Planning Ahead

While variations are inevitable, smart cost consultants plan for them from day one. Before construction begins, Quantity Surveyors often allocate provisional sums or include contingency allowances to accommodate design changes, unforeseen conditions, or regulatory shifts. In high-variation sectors like hospitality or mixed-use, a buffer of 5–15% is stated to be common. These early-stage decisions help protect the client’s budget and reduce the risk of unmanageable cost overruns later.

Tracking Variations in Real Time

Managing variation orders effectively requires more than just paperwork, it requires visibility. QSs maintain a live variation log that tracks every submitted, approved, or disputed change. These logs feed directly into monthly cost reports and client dashboards, giving stakeholders real-time insight into budget movements. Whether using simple Excel trackers or digital tools like CostX or BIM platforms, staying organised is key to cost control.

Deadlines Matter

One of the most overlooked aspects of variation orders is the notification deadline. Many UAE contracts, especially under FIDIC require contractors to notify the engineer or employer of a variation within a set period, often 28 days. If this notice is missed, even valid claims can be rejected. It’s the QS’s responsibility to monitor these deadlines, log all communication, and ensure claims remain contractually compliant.

Preliminaries and Delays

Variations that extend the project duration impact more than just materials and labour—they affect preliminaries. These are the costs of running the site day-to-day: site staff, facilities, security, insurances, and more. If a variation delays the programme, the contractor may be entitled to recover these additional costs. Quantity Surveyors assess such claims carefully to evaluate entitlement.

Disruption and Acceleration

Not all variation costs are obvious. Changes can lead to disruption when planned work is resequenced, causing delays, idle labour, or rework. In other cases, clients may request acceleration to meet original deadlines, which can involve overtime, extra labour, or fast-track procurement. These indirect effects must be priced correctly and backed by evidence, as they often lead to disputes if left undocumented.

How It Gets Approved

Variation orders must go through a formal approval process before becoming contractually binding. Typically, this involves submission by the contractor or consultant quantity surveyor, review by the cost consultant, and sign-off by the client. On government or large-scale projects, additional approvals from third-party reviewers or funders may be required. QSs ensure that each variation is fully documented, justified, and approved before implementation to avoid payment issues.

Handling VO Disputes

Despite best efforts, not all variation orders are approved smoothly. Disagreements often arise over pricing, scope interpretation, or schedule impact. In such cases, the Quantity Surveyor plays a key role in compiling evidence, preparing cost breakdowns, and supporting negotiation. If the dispute escalates, resolution may involve dispute boards (DAB), mediation, or arbitration. Early, well-documented engagement is the best way to prevent claims from becoming costly legal battles.

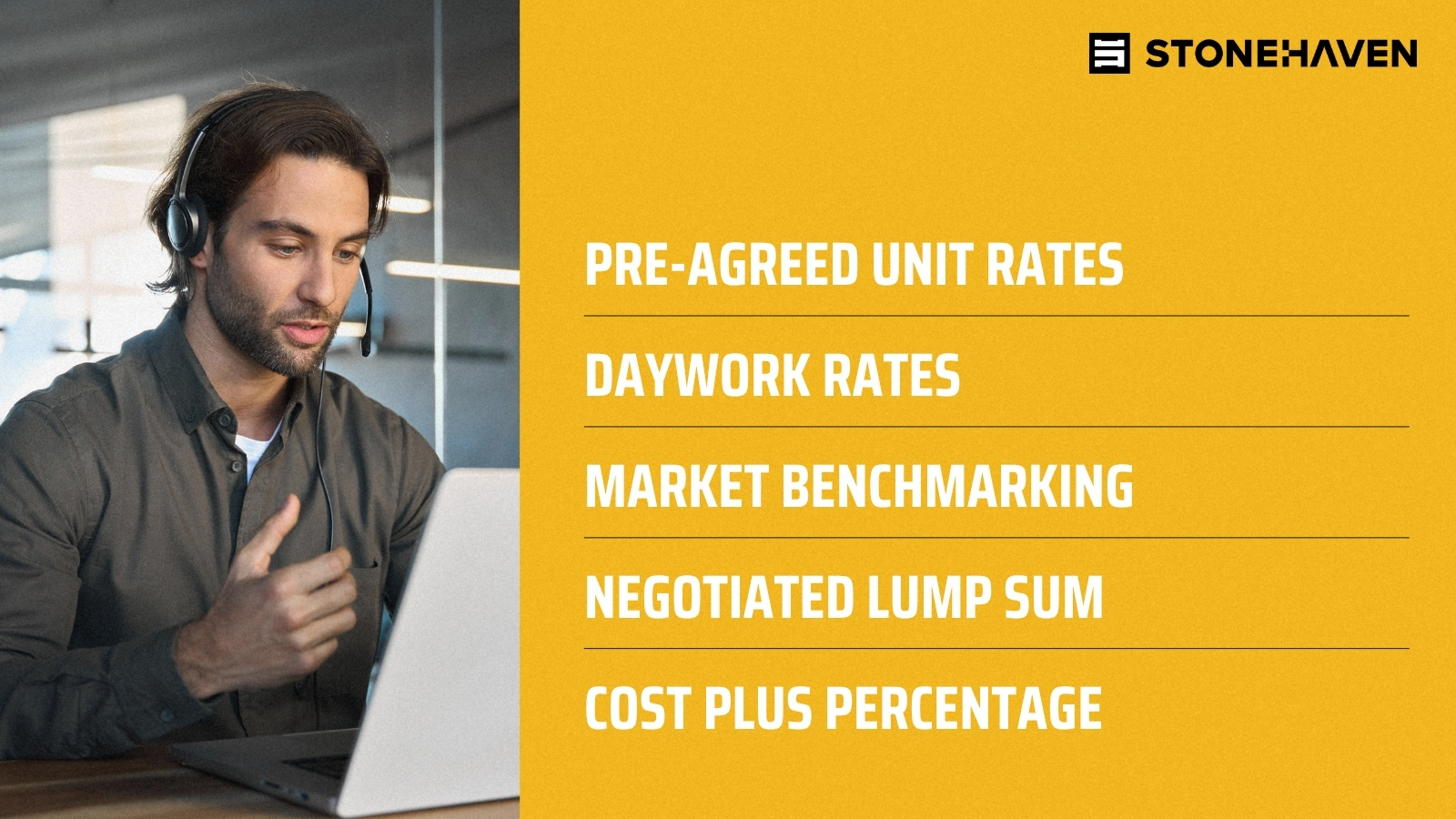

How are Variation Amounts Calculated in Contracts?

Valuing a variation order is one of the most complex and disputed aspects of construction project management. Pricing must be seen as fair, evidence-based, and in line with the contract’s pricing structure. Without clear agreements on valuation methodology, minor disagreements can escalate into major commercial disputes.

There are several standard methods for variation valuation, each suited to different circumstances.

● Pre-Agreed Unit Rates - This is often the most straightforward method. If the variation involves work items already listed in the Bill of Quantities (BOQ), the agreed unit rates are simply applied. This approach offers speed and consistency, and is particularly useful in lump sum or remeasurement contracts.

Example: If additional plastering is required due to wall changes, and plastering was already priced in the BOQ, the same rate per square metre is applied.

● Daywork Rates - This method is used when work cannot be pre-measured or scoped in advance, such as urgent or reactive changes. Contractors track hours worked, materials used, and equipment deployed, submitting daily signed logs for payment. These rates are usually pre-agreed in the contract.

Example: Emergency removal of contaminated soil or rapid waterproofing during a storm could be billed via daywork sheets.

● Market Benchmarking - When variations introduce new work items not listed in the original contract, contractors may refer to current market rates or supplier quotations. This method requires strong documentation and is often supported by third-party verification from quantity surveyors or consultants.

Example: A decision to install smart building management systems mid-project would require fresh market quotations to price the new technology.

● Negotiated Lump Sum - This approach allows both parties to agree on a total cost for the variation upfront, bypassing the need for a detailed breakdown. It’s commonly used in fast-track projects where time is critical, or when extensive negotiation would cause unnecessary delays.

Example: A fixed cost is agreed to upgrade a residential tower’s façade without the need to itemise each component.

● Cost Plus Percentage - In this model, the contractor is reimbursed for actual costs incurred, including labour, materials, and equipment, plus a fixed percentage to cover overheads and profit. It’s especially useful when the scope of work is fluid or not well-defined at the outset.

Example: A museum extension project might use this model for bespoke fit-out work involving artisan subcontractors.

Whichever method is chosen, transparency is paramount. Contractors should maintain detailed records, while clients must align approvals with broader budget controls. Many of the cost-related disputes that plague construction projects stem from unclear or inconsistently applied valuation processes, which is why clarity, consistency, and documentation are non-negotiable.

Conclusion

Variation orders are a reflection of the real-world dynamism in construction. When handled poorly, they can wreak havoc on a project's financial health and timeline. But when approached strategically, variation orders can actually enhance value, improve functionality, and reinforce client satisfaction.

In the GCC and UAE especially, where scale and complexity often define projects, understanding how to initiate, assess, and execute variation orders is a vital skill. It's a hallmark of a seasoned contractor and a professional project team.

To future-proof your projects, integrate variation order management into your broader cost management strategy. Embrace technology for real-time tracking, train teams in documentation best practices, and always maintain an open line of communication with all stakeholders.

Featured Perspective

This article includes contributions and insights from Niroshan Velu, Senior Cost Manager at Stonehaven whose project experience in the industry has shaped much of this discussion.

Niroshan Velu is a Quantity Surveyor with six years of professional experience and a Bachelor’s degree in Quantity Surveying. With more than 5 years of industry experience, he has worked on a variety of projects and developed a strong set of skills in project management, cost estimation, and risk analysis.

About us

Stonehaven is a leading construction consultancy based in the UAE, renowned for its precision-driven cost management, expert project control, and strategic advisory capabilities. Whether you’re developing a high-profile megaproject in Abu Dhabi, building a vibrant residential community in Sharjah, or retrofitting essential infrastructure in Dubai, our dedicated team ensures your vision remains aligned with your budget and project goals.

We provide comprehensive cost estimation and forecasting services that help you plan confidently from the outset. Our team is skilled at tracking variation orders in real time and guiding negotiations to protect your commercial interests. From end-to-end construction project management for developers and consultants to strategic contract administration across the GCC, Stonehaven operates with a clear focus on delivering value and reducing risk at every stage of your project lifecycle.

We also offer tailored reporting dashboards and analytics designed for executive stakeholders who require clarity, insight, and control. With Stonehaven, you’re not just engaging a consultant—you’re partnering with a results-oriented team committed to maximising your return on investment and elevating project performance.