GLOBALLY TRUSTED

MEP SUPERVISORS

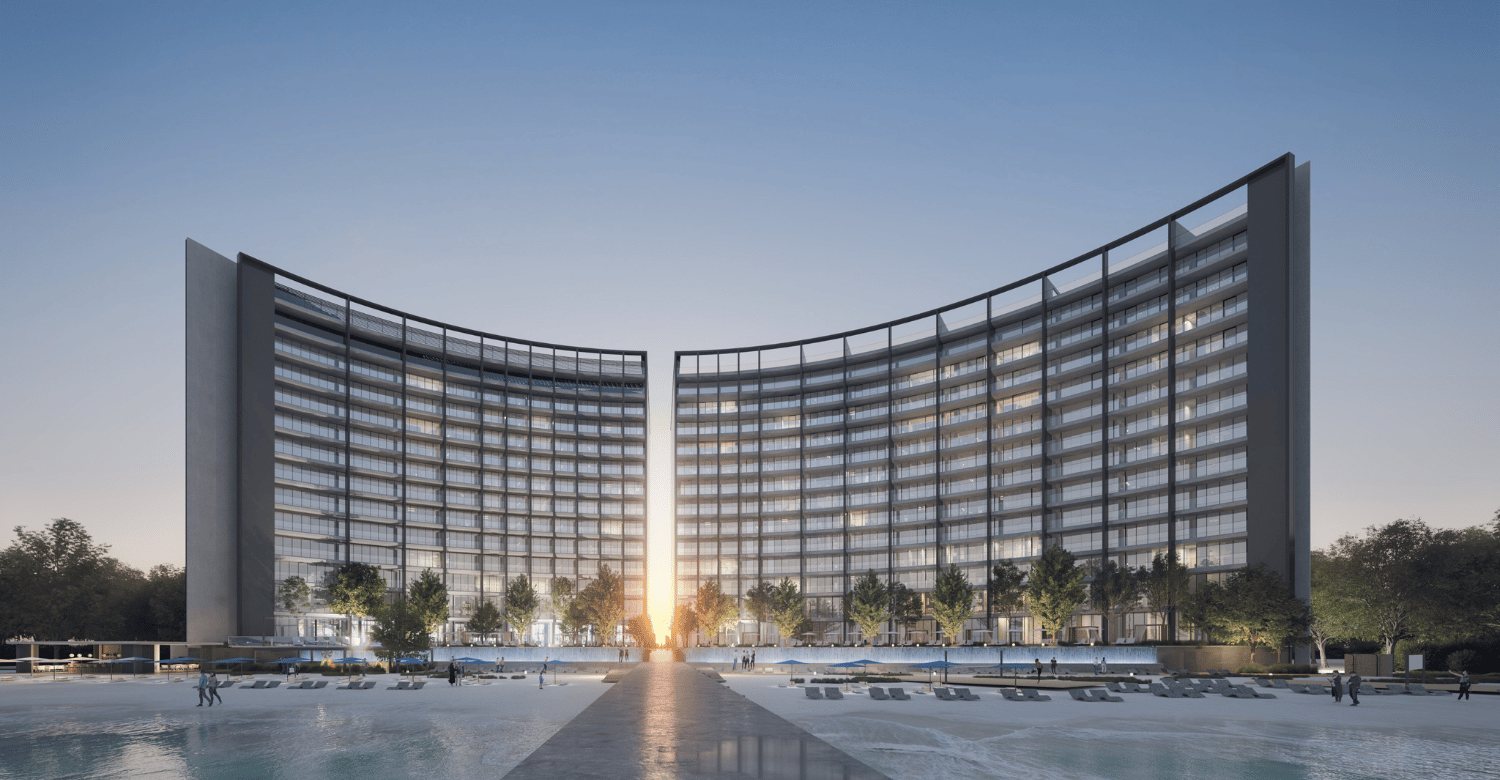

MEP (Mechanical, Electrical, and Plumbing) systems are the core infrastructure behind any building's functional behaviour. At Stonehaven, our MEP supervision teams ensure that systems are delivered to the highest standards of quality, safety, and energy efficiency for technical performance to align with architectural vision. We work with developers, consultants, and contractors across theMiddle East to coordinate complex building systems from schematic design to commissioning. Our role goes beyond compliance as we deliver MEP solutions that integrate seamlessly with architectural intent and operational goals in the Middle East.

Smarter Sustainable MEP

Our services include drawing review, on-site inspection, coordination checks, and vendor alignment across HVAC, electrical, and plumbing.

Practicality Coordination

Our experienced MEP consultants improve building quality, enhance occupant experience, and ensure that every system performs as intended.

Why STONEHAVEN

Our Clients

Our Work

Our Related Services

Frequently Asked Questions

Who are MEP supervisors?

+

Why choose Stonehaven for MEP supervision services?

+

What is the role of a MEP supervisor?

+

Does Stonehaven coordinate BIM with MEP?

+

How do Stonehaven's MEP Supervisors stand out?

+

Our Construction Supervision Insights